- Products

- Glue

- Adhesive tape

- Putty

- Resin

- Sheath

- Industrial Varnish

- Adhesive film

- Brands

- Converting

- Services

- Our locations

- Blog

- Contact

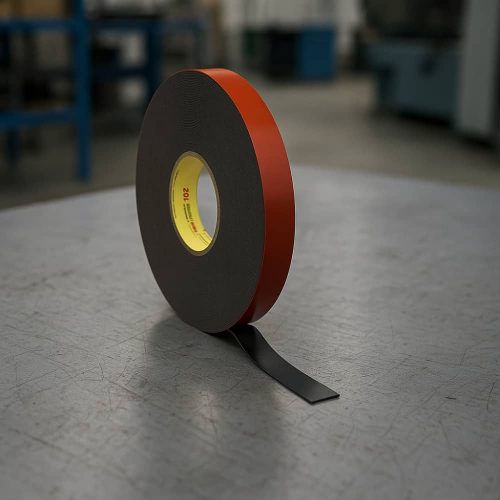

Le VHB adhesive tape (Very High Bond) is a high-performance double-sided acrylic foam tape designed to replace traditional mechanical fasteners such as screws, rivets or welds.

Developed by 3M®VHB offers a powerful structural assemblyIt is a durable and clean product, capable of withstanding the most severe mechanical, thermal and environmental stresses.

Thanks to its exclusivemodified acrylic adhesivethe VHB ribbon absorbs stress, compensates for surface irregularities, and offers excellent resistance to UV, humidity, solvents and temperature variations.

Today, it has established itself as a reliable alternative in industries as demanding as aerospace, automotive, construction and electronics.

VHB ribbon offers unrivalled superior performance:

Le VHB ribbon combines productivity, sustainabilityand aesthetics - key issues for modern industry.

VHB tape is used for fixing external components (mouldings, spoilers, signs) or bonding interior components (door panels, screens, sensors) without drilling or riveting, improving both aerodynamics and aesthetics.

In metal construction and facades, VHB tapes are used to bonding composite panels, glazing, signsand decorative structuresThe result is a neat, durable and weather-resistant finish.

Manufacturers of flat screens, smartphones, medical equipment and household appliances use HBV to assembly fine structuresguaranteeing strength and reliability without adding weight or volume.

For light aviation, drones and high-tech applications, VHB tape is used for light, strong bondingThis reduces overall weight while increasing the durability of assemblies.

At ADDEV Materialswe offer solutions Original 3M® VHB as well as optimised technical alternatives, with expert support:

Our expertise is replace conventional screws and bolts with adhesive solutions faster, more attractive, more durableadapted to your industrial requirements.

Do you have a complex assembly project or would you like to improve your productivity?

📞 Contact our ADDEV Material expertss to benefit from personalised study and discover our full range of products by VHB adhesive tapes.

VHB (Very High Bond) adhesive tape is a high-performance double-sided acrylic foam tape designed to replace traditional mechanical fasteners such as screws, rivets or welds. It provides a structural bond that is resistant to UV, extreme temperatures and vibration.

To use VHB tape, clean and dry surfaces thoroughly. Apply the tape using uniform pressure to ensure maximum contact. A cure time of 24 to 72 hours may be required to achieve maximum adhesion, depending on conditions.

VHB tape adheres effectively to a wide range of materials: aluminium, stainless steel, glass, high-energy plastics (such as polycarbonate and ABS), composites, painted surfaces and some woods.

Yes, in many cases, VHB tape can replace solder to join two surfaces together permanently, while reducing weight, improving aesthetics and better absorbing vibrations.

Yes, most VHB ribbons are designed to withstand extreme temperatures, from -40°C to +150°C, and even up to +230°C for certain specific references.

Yes, VHB tapes are formulated to offer excellent resistance to UV rays, moisture, solvents and the most demanding outdoor conditions.

Correctly applied VHB tape can last for decades, even in difficult environments, as long as the application instructions are followed (cleaning, pressure, curing time).

Yes, VHB tape is ideal for outdoor applications such as construction, glazing, signage and façade assembly.