As a partner to some of the world's leading manufacturers, ADDEV Materials combines the technical expertise of its product range with its clean-room precision laminating and cutting capabilities to provide tailor-made solutions to the major players in the Health and Wellbeing sector.

At ADDEV Materials, We design, transform and distribute technical materials designed to support innovation in the field of health and well-being.

Our Business Group Healthcare & Wellness is aimed at key European and international players medical devices, pharmaceuticals and wellness, by offering solutions that comply with the most stringent regulations (ISO 13485, FDA, cGMP).

Thanks to our industrial presence in Europe and in North America, Our technical and R&D teams support manufacturers at every stage: materials selection, prototyping, lamination and precision cutting in clean rooms and custom packaging.

Our ambition is to combine performance, safety, sustainability and customer proximity.

Wearable medical devices are revolutionising patient monitoring and follow-up.

ADDEV Materials develops biocompatible skin adhesives (acrylics, silicones, hydrogels and hydrocolloids) and conductive films designed to integrate sensors and flexible printed circuits.

Our processes for ISO 7 and 8 environmental converting provide constant quality, The result is a high-precision cut and perfect compliance with medical standards.

🎯 Objective To guarantee the reliability, skin tolerance and lasting connectivity of portable medical devices.

We design breathable films, absorbent foams and medical nonwovens for technical dressings and advanced wound care.

Our skin-friendly adhesives ensure controlled grip, This reduces the risk of irritation while guaranteeing a long-lasting hold.

The materials are selected for their water vapour permeability, their mechanical strength and their patient comfort.

🎯 Objective Accelerate healing, secure fixation and improve the comfort of care devices.

For ostomy applications, ADDEV Materials offers multilayer solutions combining barrier films, foam seals and long-lasting stick-to-skin adhesives.

Our products, designed to meet the requirements of the ISO 13485, are developed to resist humidity, limit leaks and maximise user comfort.

Thanks to our high-precision laser cutting, we can guarantee stable geometry and consistent performance over time.

🎯 Objective To ensure the safety, durability and well-being of ostomy appliance wearers.

Our material solutions support the manufacture of rapid diagnosis, biological analyses or medical samples.

We transform optical films (PET, PC, COC, COP) , and filter membranes and conductive adhesives used for immunological and molecular tests.

The operations of rolling and assembly are made in ISO 7-certified cleanrooms, guaranteeing cleanliness and reproducibility.

🎯 Objective To ensure the analytical accuracy, reliability and compliance of IVD devices.

For the pharmaceutical sector and medical devices, ADDEV Materials designs labelling systems and traceability in line with requirements FDA and cGMP.

Our labels are made from PET, PP film or technical paper, combined with acrylic or silicone adhesives resistant to extreme conditions: sterilisation, humidity, cold, solvents.

We also offer’digital or flexographic printing guaranteeing the legibility and durability of the marking.

🎯 Objective Strengthening the security of data processing and regulatory compliance.

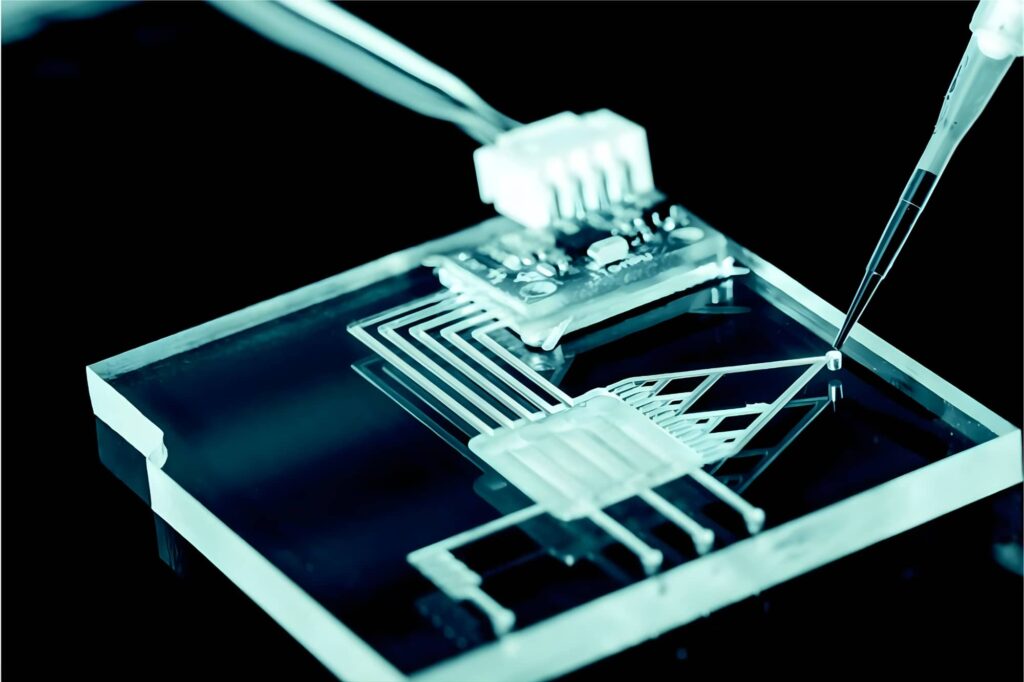

ADDEV Materials supports players in the life sciences and biomedical research in the design of microfluidic systems high precision.

Our COC / COP films with high optical clarity are combined with spacers ribbons, ventilation membranes and technical adhesives guaranteeing the cohesion of the functional layers.

Cutting is done via laser or CNC in our ISO 7 clean rooms, The result is micrometric precision.

🎯 Objective to offer reliability, cleanliness and reproducible performance for microfluidic applications.

In the field of well-being and technical cosmetics, we transform dermo-compatible films, breathable adhesives and absorbent non-wovens for cosmetic patches and dermatological devices.

Our materials are selected for their compatibility with the skin, their durability and their breathability and their moisture resistance, for a comfortable and safe user experience.

🎯 Objective To reconcile cosmetic innovation, ease of use and respect for the skin.

ADDEV Materials offers a wide range of nonwovens, PE / PU barrier films, and repositionable adhesives for professional and personal hygiene products.

Our cleanroom processing capabilities guarantee production that complies with the most stringent hygiene requirements.

🎯 Objective :offer a wide range of wipes adapted to the needs of the most demanding sectors

The choice of adhesive for medical devices depends on a number of parameters: the application surface (skin, film, sensor), the desired duration of adhesion, the biocompatibility of the material, and resistance to moisture or perspiration. Silicone or hydrocolloid adhesives are preferred for their comfort on the skin, while acrylics offer longer wear. At ADDEV Materials, formulations are tested and cut in clean rooms to guarantee safety, comfort and reliability.

Compliance is based on the selection of films and adhesives suitable for microfabrication processes and on assembly in a controlled environment (ISO 7/8 clean room). Materials must be chemically stable, have low autofluorescence and be non-reactive with biological samples. ADDEV Materials supplies COC/COP, PET or PC films that comply with European standards to ensure precision and reproducibility in diagnostic devices.

Pharmaceutical labelling must meet three challenges: traceability, durability and regulatory compliance. Adhesives must withstand sterilisation cycles, solvents and extreme temperatures, while substrates (PET, PP or technical paper) must guarantee legibility and security of the marking. ADDEV Materials offers FDA- and cGMP-compliant solutions for securing European pharmaceutical flows.

Our production sites are ISO 13485 certified and equipped with class 7 and 8 cleanrooms. These environments enable laser cutting, lamination and assembly of sensitive medical materials while controlling particles and contamination. Each batch is traceable and controlled according to a strict quality protocol, guaranteeing that our medical devices comply with European standards.

Care or hygiene devices are often in prolonged contact with the skin, so it's essential to use soft, breathable, hypoallergenic films to limit irritation. Breathable adhesives help to evacuate moisture and improve comfort of use. ADDEV Materials develops solutions combining skin comfort, durability and safety for cosmetic patches and single-use hygiene products.

Having certified sites on both sides of the Atlantic ensures proximity, responsiveness and local compliance. For European manufacturers, this means simplified logistics, controlled lead times and technical support in their time zone. For North American customers, it means FDA compliance and regulatory support in line with European standards.

Our support starts at the design stage: technical feasibility, choice of materials, rapid prototyping and validation. The teams then convert the products in a clean room, followed by packaging and certified logistics. This integrated approach speeds up time-to-market and makes industrial production of medical and well-being devices more reliable.

The durability of a skin adhesive depends on its chemical formulation (acrylic, silicone, hydrocolloid), its behaviour in prolonged contact with the skin, and its ability to maintain its adhesion despite moisture and movement. Compatibility with barrier films and sealing foams must also be considered, as well as the precision of the cut. ADDEV Materials develops multilayer solutions tested to guarantee comfort, safety and performance in ostomy appliances.

The choice of optical film depends on the type of analysis being carried out. For fluorescent tests, low autofluorescence films such as COC or COP should be preferred, as they provide optimum optical clarity and dimensional stability. Solvent and temperature compatibility must also be checked, as well as the possibility of laser cutting without distortion. ADDEV Materials supplies this type of film in custom formats, validated for European research environments.