ADDEV materials specialises in the custom conversion of high-performance materials, with a machine park of almost 300 machines. We are capable of converting flexible materials (adhesive tapes, technical films, foams, non-wovens) as well as liquids (adhesives, paints, chemicals), to deliver to our industrial customers the right part in the right format, the right product in the right dose. With 15 industrial sites around the world, we are located as close as possible to our customers, to guarantee proximity and responsiveness.

Ideal for high production volumes and complex shapes and designs.

Rotary cutting can integrate multiple tools operating in a single pass, offering the possibility of cutting different materials with distinct profiles.

It can also laminate several materials together to create a bespoke construction.

Can be adapted to both low and high production volumes, for simple shapes or complex designs including very large or very small profiles.

Flatbed die-cutting generally has lower tooling costs than rotary die-cutting, and can be particularly cost-effective for high-volume or large-scale applications.

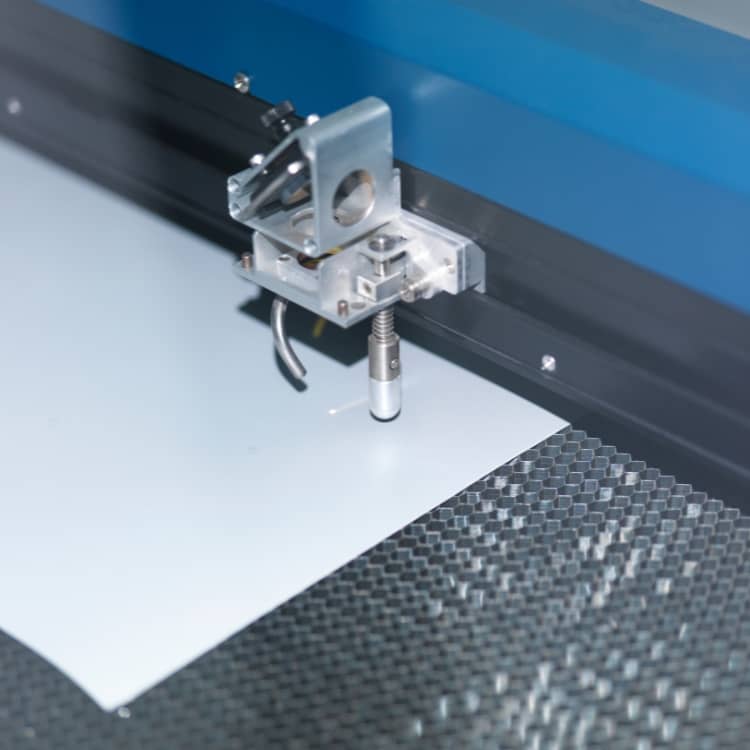

Laser cutting offers precise, clean and fast work, without the need for tools.

It is ideal for medium production runs and perfectly suited to the prototyping phase.

It can also be used to produce complex, high-precision cut-outs from DXF, DWG or AI source files.

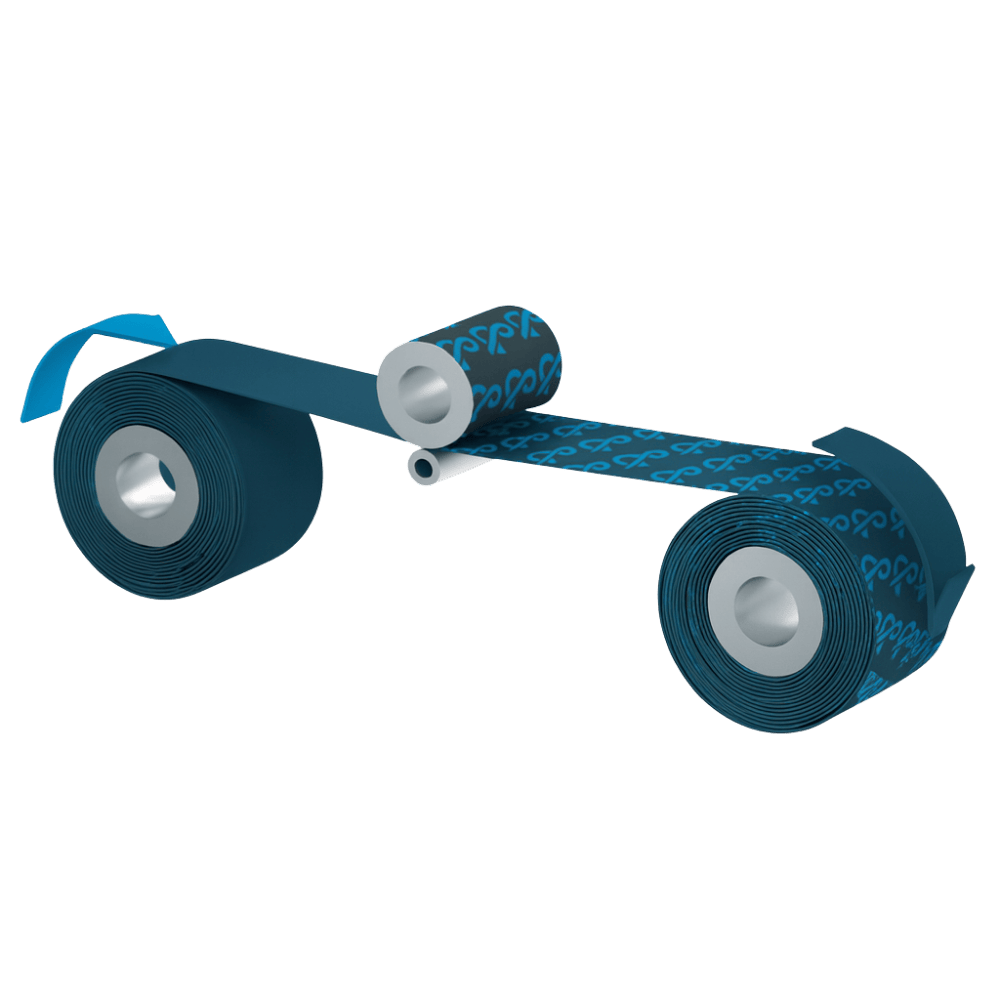

Le slitting is a process used to cut mother reels into rolls to the exact dimensions required by customers.

There are different types of slitting equipment, capable of handling a wide range of adhesive and non-adhesive materials. Our equipment guarantees optimum cutting quality.

Slitting and rewinding involves unwinding a large master roll using a series of blades, then rewinding custom width rolls onto pre-slit cores.

Le troubleshooting is an industrial process consisting of winding a strip of flexible material (technical film, adhesive tape, laminate, etc.) in crossed layers from one end of a mandrel to the other.

Unlike traditional winding, this technique produces compact, stable reels of exceptional length, making it an ideal solution for maximising production efficiency.

Le laminating is the technique of joining several layers of materials together using heat, pressure or adhesives to create unique products from similar or different materials.

We have the capacity to produce multi-laminate formats using a range of industrial laminating equipment, up to 1400 mm wide.

We are experts in flexographic printing, with a web width of up to 43 cm and up to 11 colours.

We offer four-colour printing, direct colours/Pantone metallics, UV inks and water-based inks, as well as full support in graphic art and pre-press, This is essential to ensure the success of your projects.

Our’digital printing uses a four-colour UV process, with a print width of up to 21 cm.

We operate ISO Class 7 and ISO Class 8 certified cleanrooms dedicated to the manufacture of converted products.

Cleanrooms provide an environment in which air quality, temperature and humidity are strictly controlled, protecting sensitive equipment and customer materials from contamination by dust or other impurities that could cause damage.

The integrity of the cleanroom is ensured by rigorous cleaning, regular maintenance and external validation.

Employees working in cleanrooms are equipped with appropriate clothing and follow strict working procedures at all times.

Ultrasonic welding is a fast, accurate joining process that uses high-frequency vibrations to generate localised heat and join materials without the use of adhesives or mechanical fasteners. The process guarantees excellent repeatability, short cycle times and contamination-free assemblies. It is particularly suited to aerospace applications, electrical insulation and demanding industrial environments requiring lightweight, durable components.

For plates Nomex®, For example, this technique makes it possible to produce clean, solid and reliable welds while preserving the thermal and mechanical properties of the material.

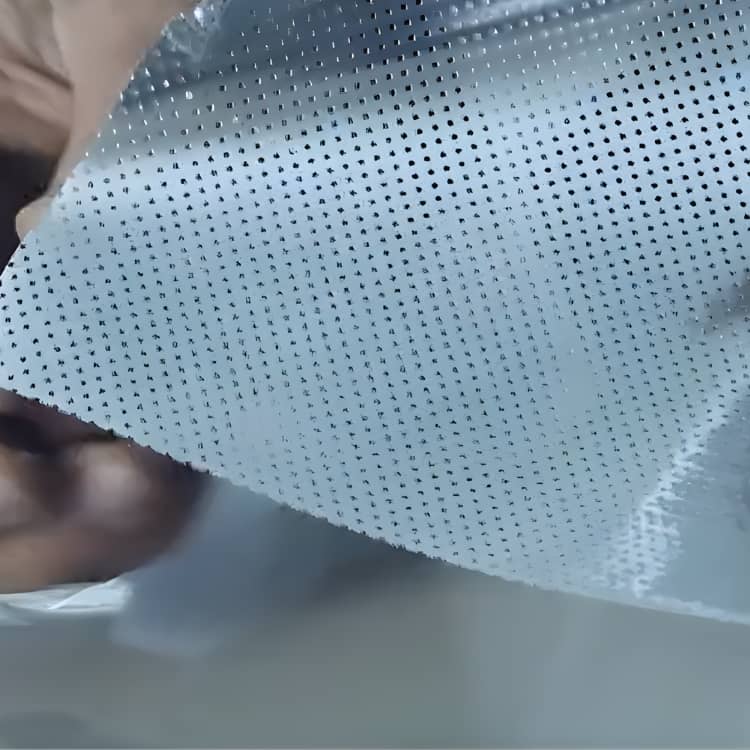

La microperforation is a process that creates extremely fine, perfectly controlled holes in flexible materials.

Using mechanical needles, laser technology or heated microtips, the film is perforated without altering its mechanical strength. This technique improves air circulation, moisture regulation and the breathability of the material while maintaining its barrier performance.

Micro-perforation is widely used for technical packaging, industrial filtration, protective films and any application requiring controlled ventilation or pressure management.

We offer advanced folding capabilities, This is particularly true of non-woven materials and technical wipes.

Our’interfolding creates perfectly layered wipes, ready for dispensing, ensuring optimal use and controlled unwinding.

Thanks to flexible tooling and automated folding systems, we can handle a wide variety of materials, formats and folding patterns while ensuring consistent quality and cleanliness.

This expertise enables us to supply customised folded products designed to meet the performance and packaging requirements of professional and personal hygiene applications.

We offer a kitting service enabling us to supply our customers with fully customised, ready-to-use sets of materials, designed to optimise production and assembly operations. Organised kits guarantee precision, efficiency and traceability.

By preparing each item in the exact format and order required, we help to reduce handling times, limit stock complexity and improve overall process reliability.

We can help you to optimise your supply chain by offering chemical packaging solutions in small unit formats that are entirely tailor-made to suit your needs and your point of use.

We are experts in accurate, economical dosing of chemicals, in the appropriate ratios. Our speciality covers the packaging of all types of products: pastes, coatings, resins, paints, mastics, gaskets, coatings, adhesives, lubricants, greases, solvents and powders.

We also take care of traceability, the shelf life and the’labelling.

As experts in the made-to-measure packaging, We have decades of experience in specialised contract packaging, with many major brands and benchmark companies among our customers.

We specialise in...

Our aim is to offer the the widest range on the market, while giving you the opportunity to work with us to design a new product. unique packaging solution, perfectly aligned with the needs of your application.

More information on our dedicated website: andpak.com

We offer advanced mixing and blending for paints and coatings, guaranteeing consistent, stable formulations.

Our controlled processes ensure precise ratios, excellent repeatability and complete traceability of each batch.

This service provides ready-to-use products tailored to customer specifications, improving efficiency and reducing on-site handling.

Our pre-freezing service guarantees optimum stability and extended shelf life for sensitive chemicals.

The materials are dosed with optimum precision, packaged and then frozen under strictly controlled conditions to preserve their performance from production to end use.

This solution improves process reliability, reduces waste and meets the stringent quality and regulatory compliance requirements of high-performance industries.

We offer wipes impregnation services guaranteeing homogeneous, clean, precisely dosed wet wipes for industrial and aeronautical applications.

Each wipe is uniformly saturated with specially formulated chemicals, ensuring performance, safety and ease of use.

This process improves application efficiency while reducing the variability and handling of chemicals on customer sites.

More information on our dedicated website: andpak.com

ADDEV Materials stands out for its comprehensive expertise in converting and processing high-performance materials, backed by robust industrial resources and an international network. Our added value is based on our ability to combine technical expertise, multi-technology processing and high quality standards, We are committed to providing parts, rollers and solutions that are perfectly adapted to the needs of the most demanding manufacturers.

Thanks to more than 30 cutting technologies, of multi-layer lamination, d'printing, of reconditioning, of mix, and ISO Class 7 and 8 certified cleanrooms, We offer solutions for the most critical sectors: aeronautics, healthcare, electronics, energy, mobility, industry, point-of-sale advertising, transport and packaging.

Our expertise covers the entire industrial cycle:

Selecting materials (technical films, foams, adhesives, composites)

Made-to-measure transformation (laser cutting, rotary, flatbed, laminating, slitting, etc.)

Prototyping and industrialisation

Custom packaging for liquid materials (Clip-Pak®, BurstSeal-Pak®, syringes, pens, tubes, bottles)

Regulatory support and traceability

In addition to its technologies, ADDEV Materials stands out for its technical support, his control of critical environments, and the ability to propose solutions operational, fast and reliable, These systems can be perfectly integrated into our customers' production lines.

👉 For all your converting, of cut to size, of custom packaging, or the development of ready-to-use technical solutions, We have a team of dedicated experts ready to turn your problems into high-performance industrial solutions.

Industrial converting refers to all the processes used to transforming flexible materials (films, foams, adhesives, composites) in customised parts, rolls or kits. It is used to adapt a standard material to the specific needs of a process, piece of equipment or industrial application.

An expert in converting masters several technologies, guarantees repeatability, the precision, the quality and the regulatory compliance. It can transform, combine and adapt materials to obtain a result that is perfectly compatible with the mechanical, thermal or regulatory constraints of the sector in question.

We process a wide variety of materials: technical films, foams, adhesives, nonwovens, membranes, composites, as well as liquids packaged in appropriate formats (syringes, pens, tubes, sachets, Clip-Pak®, BurstSeal-Pak®). Each material is selected according to its performance and industrial compatibility.

The choice depends on the geometry, the tolerance, the quantity, the type of material and process constraints. Our experts identify the most appropriate technology - laser cutting, flatbed, rotary, lamination, slitting, foaming, printing - to ensure optimum performance and controlled costs.

Tailor-made packaging improves the dosing precision, the safety in use, the repeatability, and reduce the risk of error. Suitable formats (syringes, pens, tubes, sachets) make it easy to integrate them into production, so they can be used cleanly, quickly and in regulated environments.

Yes. Our teams take part in engineering, prototyping and qualification phases, The aim is to select the right materials and design a technical solution that is compatible with the customer's performance and productivity objectives.

Converting expertise is essential in the’aeronautics, the health, l’electronics, the energies, l’automotive, the rail, the POS, the packaging, l’general industry and all applications requiring precision, security, traceability.

Quality is based on a combination of appropriate technologies, of strict controls, of certified processes and a complete traceability system. Our ISO Class 7 & 8 cleanrooms and automated equipment guarantee optimum reproducibility, even for complex geometries.

Yes. We make kitting, the custom packaging, the preparation of cut parts, and formats adapted to machines or complete ready-to-install kits, This facilitates rapid implementation and reduces the risk of errors.

You can contact our teams directly from the dedicated page. An expert will analyse your needs and suggest the most suitable solution: converting, cut to size, packaging, kits, prototyping, or specific developments.