At ADDEV Materials, We believe that no standard solution can meet all industrial needs. Every process is unique, every market has its own constraints, and that's why we're banking on the flexibility of our solutions.’collaborative innovation to design tailor-made solutions.

Our aim is twofold: to improve operational performance of our customers while reducing’environmental impact their processes through a responsible and sustainable approach.

At ADDEV Tech, We transform industrial challenges into sustainable, high-performance materials solutions. Our mission : co-developing tailor-made solutions with our customers, From idea to production, combining materials expertise, advanced processes and a responsible approach.

Our Technical Application Experts support customers from the earliest stages, with feasibility studies, technical advice and co-development workshops.

Their role is to make the link between application needs and R&D solutions, to create innovations that are adapted and directly operational.

Thanks to our laboratories and specialised equipment (ISO Class 7 & 8 certified clean rooms, heating presses, screen printing, tests in controlled environments, etc.), we can quickly validate concepts by rapid prototyping and proof-of-concept.

This experimentation capability helps to reduce time-to-market while optimising the performance of materials.

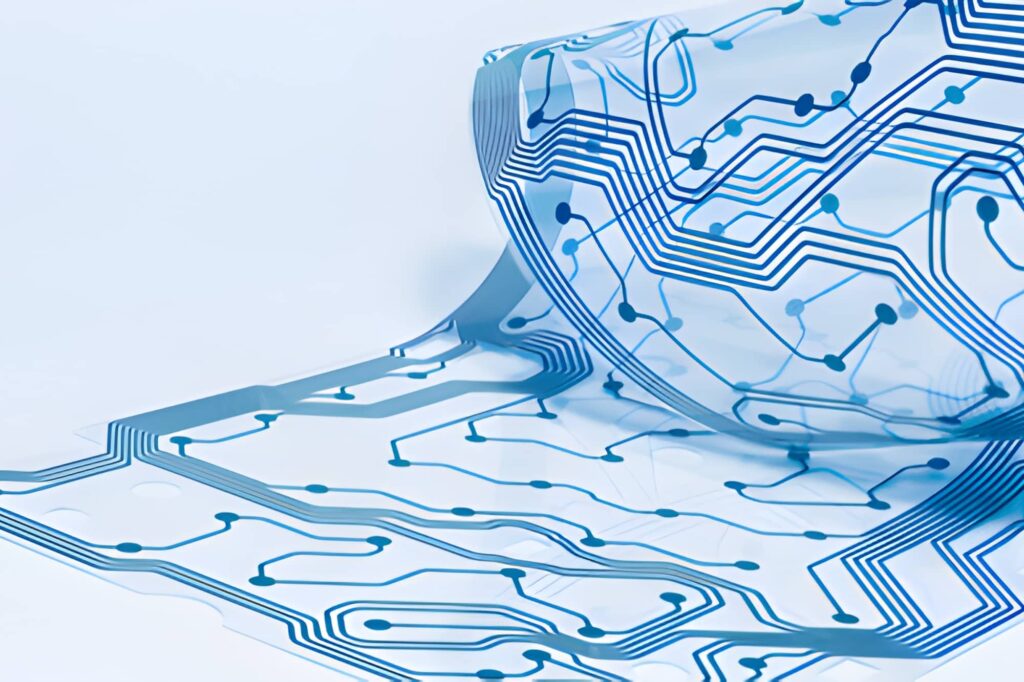

We go beyond simple transformation by proposing the functionalisation of materials conductive films, flexible substrates, printed inks, thermal management solutions.

We create customised, functional designs for critical applications in the aerospace, energy, medical and electronics industries.

Innovation at ADDEV Tech is part of a responsible approach. We integrate’eco-design from the earliest stages of development, This is achieved by focusing on recyclability, repairability and reducing the carbon footprint.

With our in-house tool LEA - Life Cycle Evaluation by ADDEV Materials, We measure the environmental impact of our products and processes in order to identify the best alternatives.

Ultra-thin, light and flexible heating film for the thermal management satellites, batteries and critical systems.

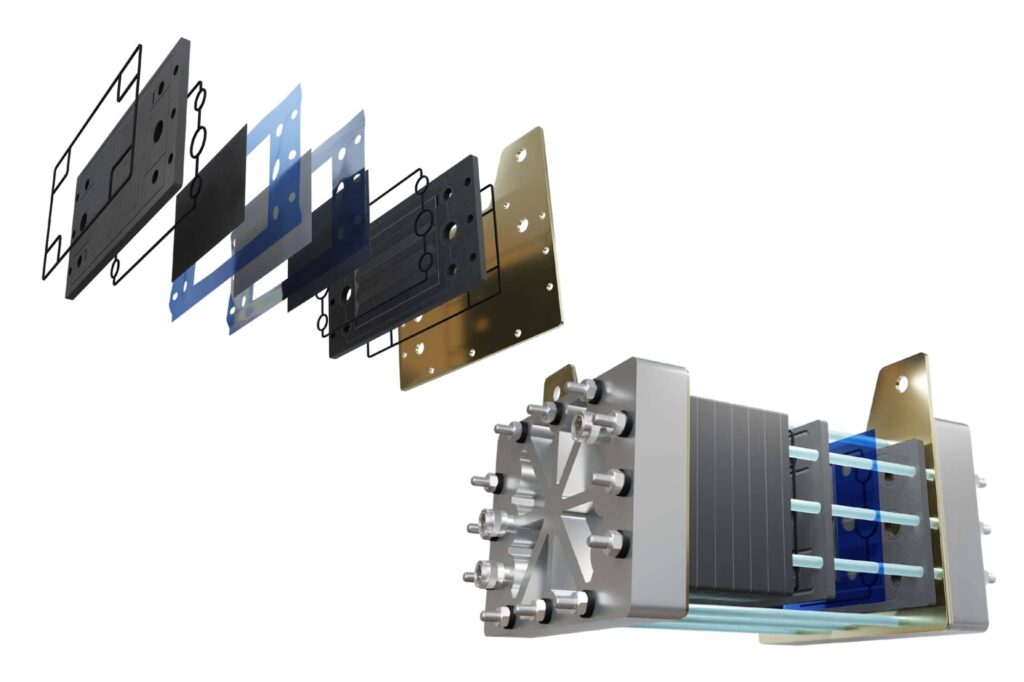

Functionalised subgasket to improve the performance and reliability of PEM/AEM fuel cells and electrolysers.

Self-healing coatings for surface protection, multilayer films for photovoltaics, printed sensors for thermal and pressure monitoring.

💡 Our ambition is to work with you to develop the solutions of tomorrow, which are more efficient, more responsible and quicker to industrialise.

We develop and select high-performance materials technical films, foams, adhesives, sealants, chemicals and non-wovens, adapted to the most demanding environments.

Our capacity to converting (cutting, laminating, forming, ultrasonic welding, printing, etc.) enable these materials to be customised to perfectly meet the needs of each customer.

Our solutions for custom packaging - cartridges, Clip-Pak®, Burstseal-Pak®, The use of a wide range of products, such as spray bottles, syringes and wipes, simplifies product application, reduces waste and reduces exposure to risks.

Innovation at ADDEV Materials is part of a responsible approach:

Each innovative project is designed to generate a measurable impact:

💡 “Thousands of solutions exist. One of them is optimal. Let's create it together.” - The ADDEV Tech team

We innovate to support the aviation, space, defence and MRO industries.

Our work is part of a more sustainable chemistry approach, working on chromium-free formulations that limit VOCs.

We are developing containers made from recycled materials, which are more environmentally friendly, or reusable, to limit waste.

We also offer innovative technical solutions, such as metallised or perforated films, to meet the requirements of the space sector.

Our teams develop materials solutions for the medical and well-being sectors in ISO 13485-certified cleanroom environments.

Advanced wound care solutions, portable adhesive devices, microfluidics: we transform and combine advanced flexible materials, medical adhesives, technical films, foams and sterile packaging to meet the ever-changing needs of the medical devices market, guaranteeing quality, traceability and regulatory compliance.

Industrial processes are integrating more and more electronics, increasing the need for sealing, protection and thermal management.

Our innovative solutions are aimed at devising the most effective material solutions (technical adhesives, thermal pads, mastics, glues and resins) to protect and guarantee the durability of the most sensitive components.

Energy transition, sustainable mobility, artificial intelligence: these fundamental trends are having an impact on the energy, automotive and rail markets.

Our innovations focus on electrical and thermal insulating materials, EMI shielding and thermal management solutions for batteries and digital infrastructures.

They increase the reliability of systems while reducing their environmental footprint.

👉 Contact our Innovation experts to discuss your projects and discover our solutions tailored to your market.