Electrical insulation and thermal management are at the heart of the reliability and safety of modern electrical systems. Without them, no infrastructure, no machine, no energy distribution network could operate safely and sustainably.

ADDEV Materials in figures

in sales

employees worldwide

including 15 manufacturers in Europe, North America and Asia

achieved internationally

Without controlled insulation and optimum heat management, no machine, no energy distribution network and no electric mobility solution could operate safely and sustainably.

Whether it's high, medium or low voltage transformers, industrial motors, batteries for electric mobility and stationary or industrial applications, or cables for intelligent buildings, the combination of high-performance insulation and efficient thermal management determines the longevity and reliability of systems.

ADDEV Materials has established itself as a benchmark partner for manufacturers looking for reliable, innovative and durable high added-value solutions to protect, insulate and optimise the performance of their equipment.

ADDEV Materials, experts in electrical insulation and thermal management

ADDEV Materials is a French industrial ETI with an international dimension, specialising in the manufacture of processing of technical materials (films, non-wovens, adhesives, resins, varnishes, sheaths, etc.).

With over 40 years' experience and a network of 15 sites in Europe and North America, we support players in the energy, mobility, rail, aeronautics, medical and construction sectors in the design and optimisation of electrical insulation solutions.

Our raison d'être« Converting industrial challenges into sustainable material solutions »Our mission is to transform your technical constraints into high-performance, sustainable solutions.

Electrical insulation and thermal management for system performance

Electrical insulation and thermal management are not just factors of protection: they are decisive factors in the reliability, the security and the energy performance systems.

ADDEV Materials operates across the entire energy chain, supplying materials adapted to each stage, from production to storage, transmission and distribution.

Energy conversion and transmission

Transformers, alternators, generators and converters require very high quality insulation to withstand extreme voltages and thermal stresses.

ADDEV Materials supplies :

- From insulating film and paper Nomex®, mica tapes, cellulose paper, polyester.

- From impregnating resins and varnishes to strengthen windings and improve dielectric strength.

- From IEC and UL certified solutions, covering high and medium voltage applications.

Energy storage and electric mobility

The development of electric mobility and energy storage imposes new requirements in terms of insulation and thermal management.

ADDEV Materials offers :

- From insulating film and paper, and ducting systems heat dissipation.

- Solutions for fire barrier for electric and industrial batteries.

- Innovations such as NeoHeater®, heating film for thermal management, and Subgasket®, The new Hydrogen Gasket, an insulation and sealing solution for hydrogen systems (fuel cells, electrolysers).

Industrial electrical applications

Motors, rotors, stators and industrial equipment require insulation that can withstand high mechanical and thermal stress.

ADDEV Materials offers :

- Materials such as Nomex®, and laminated films, and tubes, from insulating jackets and micaceous ribbons.

- From varnishes and resins to reinforce winding protection.

- Solutions to ensure reliability, reduced wear and extended service life electrical equipment.

Electrical equipment and infrastructure

Our expertise extends to cables, busbars, systems medium and low voltage and human-machine interfaces (HMI).

ADDEV Materials supplies :

- From PET and polyimide films, insulating jackets, resins and adhesives.

- Reliable and sustainable solutions for electricity infrastructures and intelligent buildings, guaranteeing performance and safety.

ADDEV Materials, expertise for all phases of your projects

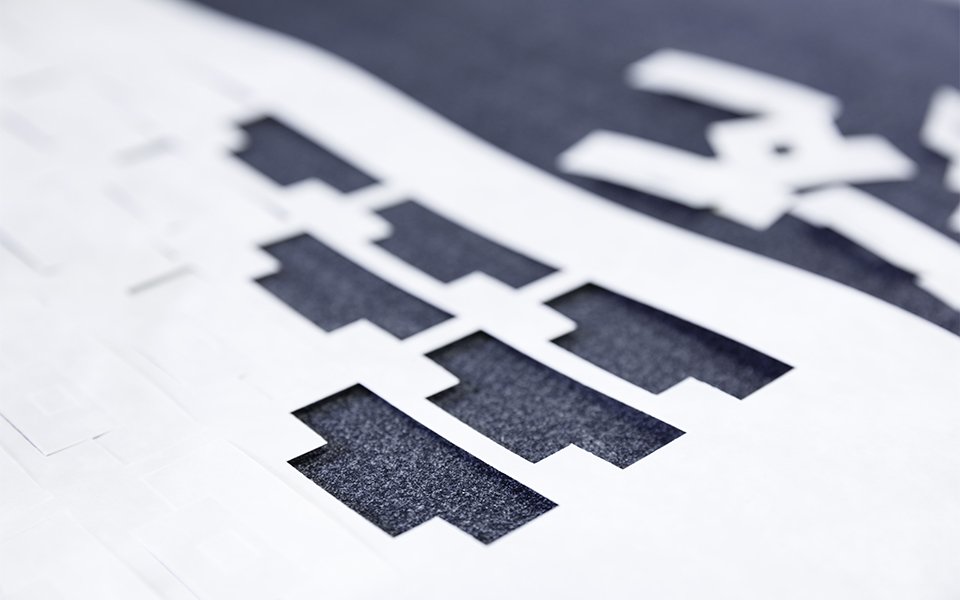

Transformation and design of technical materials

Thanks to our expertise in converting, we can source, formulate and transform a wide range of materials:

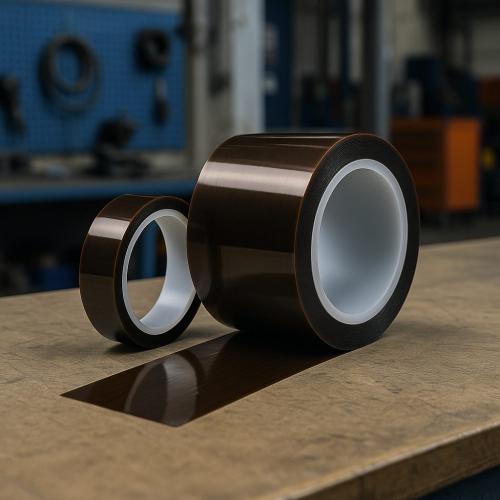

- Electrical tapes (adhesive)

- Technical films

- Laminated

- Cellulose paper

- Resins

- Sheaths and foams

To design tailor-made solutions that meet the most stringent requirements in terms of insulation, protection and industrial performance.

Support from prototyping to production

Our teams of experts support customers from the design phase through to production, including prototyping, testing and validation.

This support is essential to guarantee optimised solutions, perfectly tailored to the needs of each project.

Mutlimarket expertise

Our solutions can be found in many sectors:

- Energy networks

- Mobility and electric mobility

- Rail & MRO

- Construction & Smart City

- Infrastructure

This cross-disciplinary approach enables us to innovate by crossing technologies from one market to another.

Tailor-made solutions thanks to our industrial capabilities

ADDEV Materials stands out for its advanced industrial capabilities, which enable us to transform raw materials into customised solutions that meet the most stringent requirements.

Our processes guarantee consistent quality and the flexibility to adapt to the most complex projects.

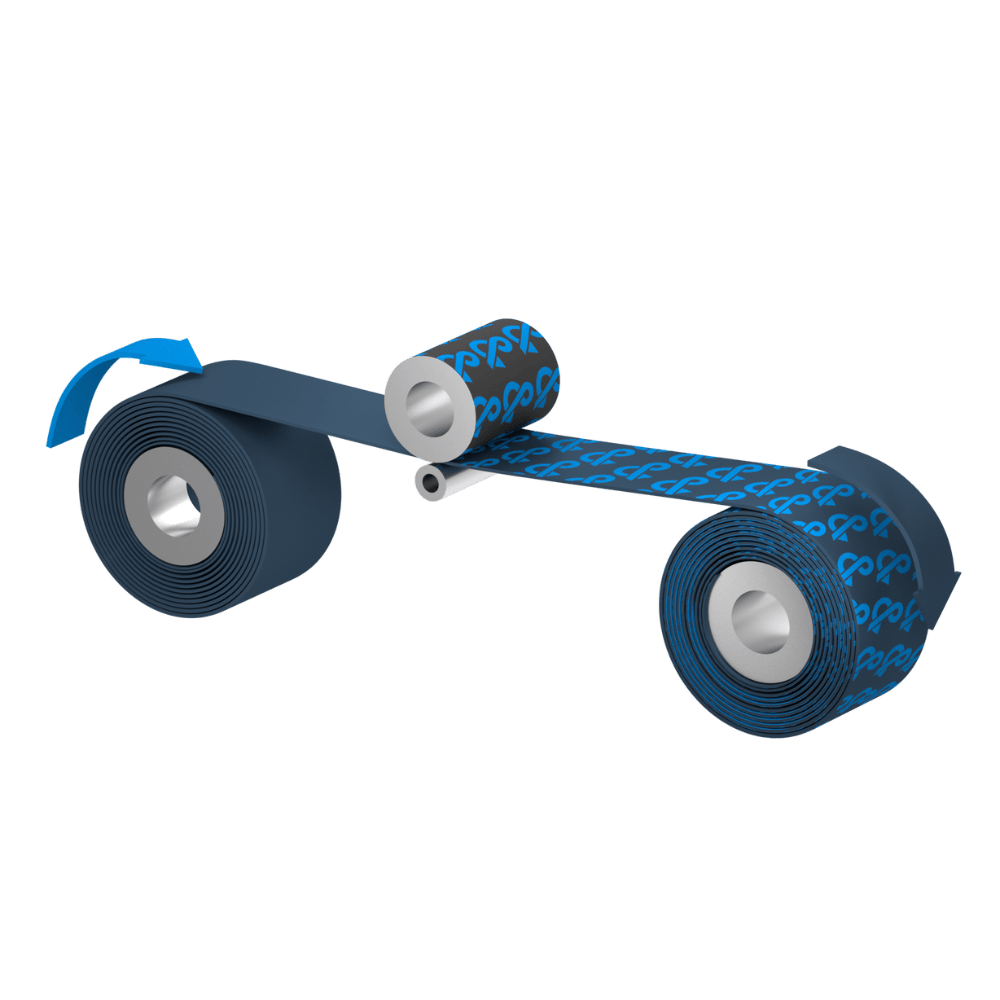

Our transformation processes

Slitting

Precision cutting

Lamination

Ultrasonic welding

Kitting

Packaging

Benefits for our customers

Longer service life for electrical components.

Optimising heat dissipation and improving energy efficiency.

A response to the miniaturisation and integration constraints of modern systems.

Do you have a complex project requiring expertise in insulation or thermal management? Contact our experts or download our white paper to find out more.

ADDEV Materials, expertise in materials, processes and innovation

Innovation is at the heart of ADDEV Materials' strategy. Thanks to our ADDEVTECH, We develop advanced solutions that meet performance requirements while incorporating eco-design principles.

ADDEVTECH: our innovation engine

ADDEVTECH is our collaborative research and innovation centre.

It enables us to co-develop solutions with our customers, anticipate future needs and incorporate the latest technological advances.

We work in partnership with manufacturers, and start-ups and research centres.

Our major innovations

Sustainable commitment

We are one of the top % most virtuous companies, with a certification of EcoVadis Platinum.

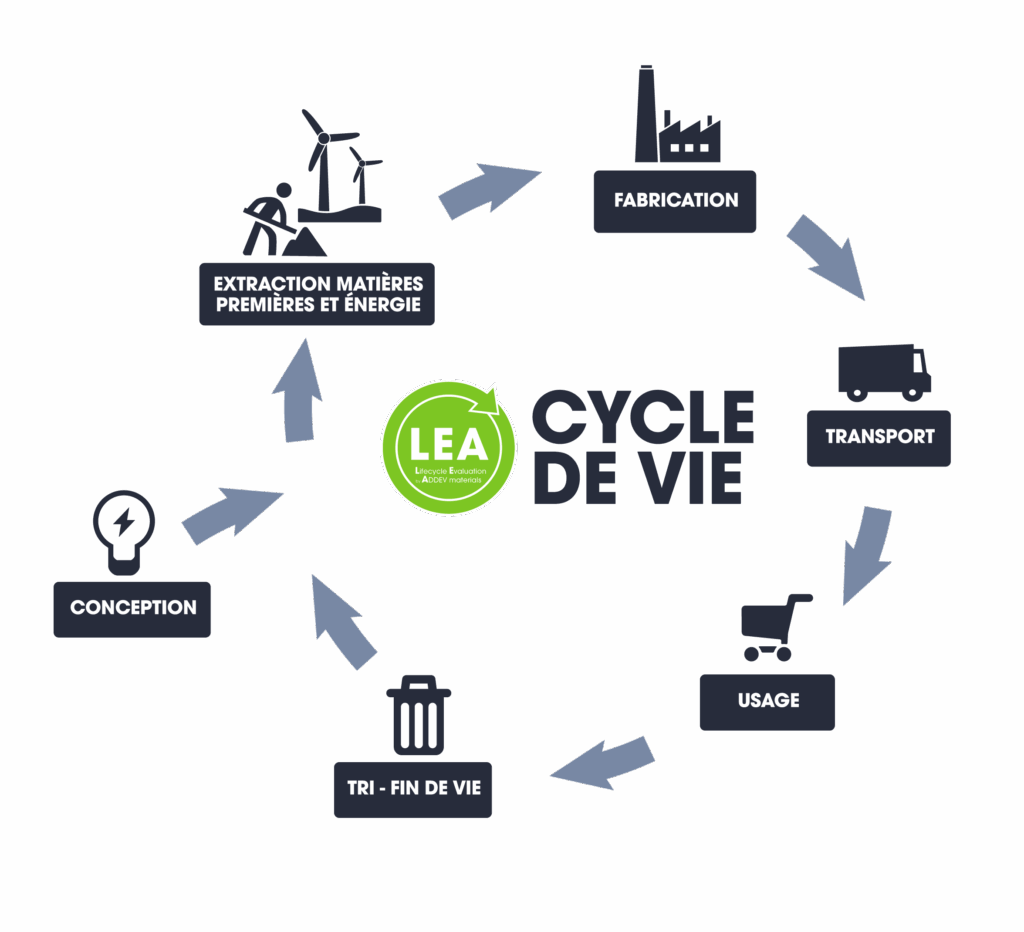

Our solutions focus on recyclability, repairability and a significant reduction in the carbon footprint thanks to our tool LEA (Life Cycle Evaluation), which analyses the environmental impact of each product throughout its life cycle.

Our strategic partners and brands

Our reference suppliers and partners

For many years, ADDEV Materials has maintained solid, long-term partnerships with some of the biggest names in the technical films and fibres industry, including DuPont™ Tedlar®, DuPont™ Mylar®, Dupont Laird™, Rogers® and 3M™.

These trusted partnerships give us access to the highest-performing materials on the market and guarantee our customers reliable, traceable and sustainable solutions. Thanks to this long-term relationship, we can transform films, papers and foams for thermal management and electrical insulation into tailor-made technical solutions that meet the most demanding requirements in the following sectors energy, mobility and industry.

These partnerships contribute to the quality, reliability and compliance of our solutions with international standards.

Our customer references

ADDEV Materials is proud to support leading companies in their respective fields:

- Energy and infrastructure: Schneider Electric, Legrand, Hagergroup, Nidec...

- Mobility: Valeo, Hitachi, Delphi, Alstom...

- Smart Building and city : Somfy...

Energy and infrastructure

Schneider Electric

Legrand

Hager

Nidec

Mobility

Valeo

Hitachi

Delphi

Smart Building and City

Somfy

These collaborations testify to our ability to meet the most stringent requirements in terms of electrical insulation, whether for high-tech projects, industrial applications or critical infrastructures.

Our locations

FAQ - Electrical insulation, performance and thermal management

Electrical insulation prevents current from escaping, protects users and avoids short circuits. It is essential to guarantee the safety, performance and longevity of equipment.

We offer a complete range of materials: Nomex®, Kapton®, mica tapes, PET films, fibres, non-wovens, technical and cellulose papers, resins, sheaths and tubes. Each application requires the right combination to guarantee safety and performance.

The rotor (the moving part of a motor) and the stator (the fixed part) are subject to different mechanical, thermal and electrical stresses. We provide specific solutions for each, capable of withstanding vibrations and high temperatures.

Our solutions are designed with eco-design in mind. We favour recyclable materials and optimised processes, and we use our LEA tool to measure and reduce the carbon impact of each project.

Absolutely. We co-develop specific solutions with our customers, from the prototyping phase through to series production, to meet precise and complex requirements.