MADE IN USA, SINCE 1975

As a specialist in technical material converting, ADDEV Materials Converting supports players in the automotive, industrial, and electronics markets in the design and optimization of their assembly, insulation, and protection solutions.

Through our expertise in die-cutting, slitting, laminating, and forming of films, adhesives, and insulation materials, we deliver custom-engineered components that are reliable, high-performing, and suited for the most demanding environments.

We work in close partnership with our customers, from the prototyping phase through full-scale production, ensuring quality, precision, and industrial excellence.

We work with a broad portfolio of technical materials including films, foams, adhesives, sealants, non-wovens, laminates and more. We meet the specific needs of Automotive, Industry & Electronics applications while complying with the standards required by the following globally recognized certifications:

Glenshaw, PA site is ADDEV Materials’ Automotive Center of Excellence at group level.

This is where we specialize in converting technical materials for the assembly of interior and exterior components for the world’s leading automotive manufacturers.

Awarded the General Motors Supplier Quality Excellence Award for 12 consecutive years, our expertise in the automotive sector is highly valued by both our customers and suppliers.

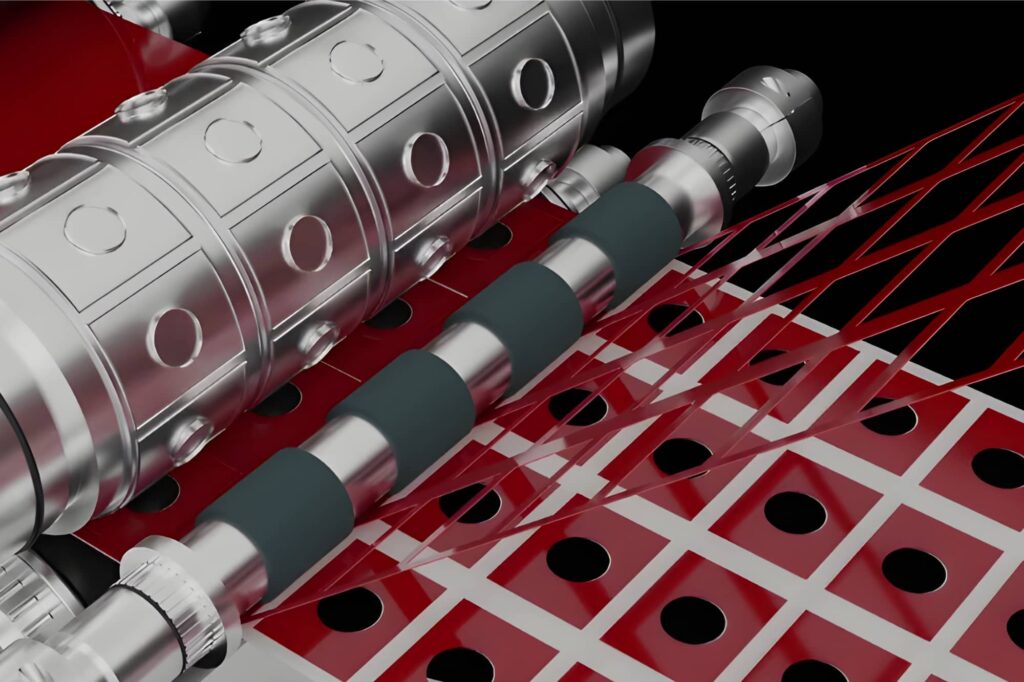

The most demanding Industrial challenges require customized solutions. That’s why we combine our materials expertise with advanced converting technologies such as high-precision rotary and flatbed die-cutting, laser and CNC cutting, multilayer lamination, slitting, rewinding, spooling, cleanroom manufacturing and packaging.

I always enjoy working with the folks at Addev Materials who help me tackle my challenging converting needs. Great people and great quality work.

thanks for all your support and follow up regarding all my request, your response is pretty quick and punctual, the material I am looking for meets all expectation for our company needs, Thanks for your support you are providing us. Cheers and look forward working with you.

The ADDEV Materials Converting facility in Glenshaw is located approximately 20 minutes north of downtown Pittsburgh. The site offers easy access from major highways while remaining outside the city’s main traffic congestion, making it convenient for customers across the greater Pittsburgh industrial area.

Customers and partners are welcome to visit the Glenshaw facility to meet the local team, review capabilities, and discuss converting projects on site.

Industrial converting is the process of transforming raw materials (such as foams, films, adhesives, and many more technical materials) into custom-engineered components ready for integration into finished products. For OEM manufacturers, converting improves production efficiency by delivering parts in the right format, size, and performance level. Through precision processes and material expertise, ADDEV Materials Converting helps OEMs reduce assembly time, improve consistency, and optimize overall manufacturing performance.

The ADDEV Materials Converting facility offers a wide range of industrial converting processes designed to support OEM, Tier 1, 2 & 3 manufacturing needs. Capabilities include rotary die-cutting, flatbed die-cutting and laser cutting for precision-shaped components, as well as laminating and multi-layer laminating to combine multiple materials into high-performance assemblies. The site also provides on-roll slitting, along with unwinding and rewinding, enabling materials to be supplied in formats optimized for efficient downstream production.

The ADDEV Materials Glenshaw facility converts a broad range of technical materials to meet industrial and OEM requirements. These include adhesive tapes, technical films, foams, foils, non-wovens, and engineered laminates. By working with both single-layer and multi-layer material constructions, the site supports custom converting solutions tailored to specific applications, performances, and manufacturing constraints.

ADDEV Materials Converting serves a wide range of industries, providing custom converting solutions for automotive, industrial manufacturing, construction, electronics, power and energy, and healthcare sectors. By tailoring converting processes and material selections to each industry’s unique requirements, ADDEV Materials Converting helps OEMs and manufacturers improve production efficiency, product performance, and consistency across applications.

Yes, ADDEV Materials Converting has a team of material experts who work closely with customers to identify the most suitable solutions for their applications. Leveraging extensive experience with adhesive tapes, technical films, foams, foils, non-wovens, and laminates, the Glenshaw team provides guidance on material selection, performance optimization, and compatibility with converting processes, ensuring that each solution meets the specific requirements of OEMs and industrial manufacturers.

Yes, ADDEV Materials Converting supports both prototype development and small production runs for OEMs and industrial manufacturers. Thanks in part to advanced capabilities such as CNC laser cutting, alongside rotary and flatbed die-cutting, laminating, and slitting, the Glenshaw team can quickly produce custom components for testing, evaluation, and low-volume production. These capabilities help customers accelerate product development, validate designs, and reduce time-to-market while maintaining high quality and consistency.

ADDEV Materials Converting maintains the highest standards of quality and environmental responsibility to support OEMs and industrial manufacturers. The site is ISO 14001 certified for environmental management, IATF 16949 certified for automotive quality systems, and ISO 13485 certified for medical device components. Additionally, ADDEV Materials Converting is a 3M Preferred Partner and holds Ecovadis Platinum recognition for sustainability and corporate responsibility. These certifications and partnerships ensure consistent, reliable production and demonstrate the Glenshaw facility’s commitment to excellence in converting processes.

ADDEV Materials Converting ensures repeatability and consistency in its converting processes through a combination of advanced equipment, rigorous quality controls, and experienced operators. By using precision technologies such as CNC laser cutting, rotary and flatbed die-cutting, laminating, and slitting, along with robust inspection protocols at every stage of production, the Glenshaw team guarantees that each batch of material meets exact specifications. These practices allow our customers to rely on ADDEV Materials Converting for highly consistent, reliable components across both prototypes and full production runs.

Choosing a local partner like ADDEV Materials Converting in Glenshaw provides significant advantages for OEMs and Tier 1, 2, and 3 suppliers. Local operations ensure faster turnaround times, lower shipping costs, and more flexible production schedules, while allowing direct collaboration with material experts to tailor solutions for specific applications. Working with a nearby converting facility also reduces supply chain risks and enables on-site support, inspections, and quality verification, ensuring reliable, high-quality components for industrial manufacturing.