- Products

- Glue

- Adhesive tape

- Putty

- Resin

- Sheath

- Industrial Varnish

- Adhesive film

- Non-woven

- Brands

- Converting

- Services

- Our locations

- Contact

Le complexing and theadhesion are two industrial transformation processes that involve combining different technical materials to give them new functional properties.

Le complexing can be used to assemble several layers of film, fabric, paper, foam or liner to create a multi-layer structure with enhanced characteristics (thermal, acoustic, mechanical barrier, etc.).

L'adhesionTechnical adhesive bonding involves applying a technical adhesive to a bare or laminated substrate, to make it ready for integration into your assembly or installation processes. This operation can be carried out on a full surface or in zones, using acrylic, double-sided, silicone or repositionable adhesives.

Adhesive coating is a process whereby an adhesive layer is applied to a material.

The adhesive is applied to the material using a “dry phase” method to form a single product which has the properties of the combination of the material + adhesive.

The primary purpose of adhesive coating is to turn a non-adhesive material into an adhesive material.

Our made-to-measure adhesive service is used in many industries to facilitate the assembly, fixing or protection of technical components:

Fixing decorative or functional films to panels

Installation of acoustic or thermal foam with pre-applied adhesive

Creation of double-sided supports for cables or sensors

Temporary protection of painted, polished or glazed surfaces

Mobility automotive, rail, aerospace

Electronics assembly of sensitive components

Building & construction insulation, interior finishing

Medical : technical adhesives for devices and sensors

Technical packaging complex double-sided tapes or liners

Complexing is the process of bonding two or more strips of a flexible or rigid backing material together using a technical adhesive.

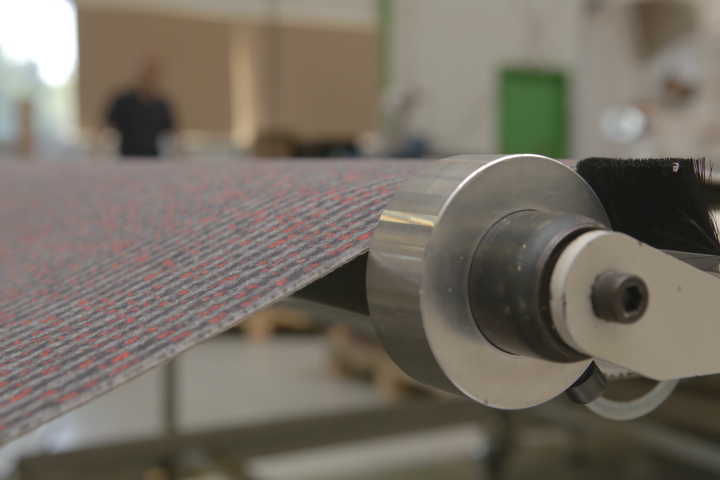

These strips may be made of plastic film, paper or a metal foil/thin material. The adhesive is applied to the least absordent strip which is then bonded to the second strip by the high pressure exterted by heated cylinders, in order to produce an ultra strong assembly. This assembly may comprise two layers (duplex), three layers (triplex), or more…

Complexing improves the appearance and barrier properties of the strips. The type of adhesive selected is primarily dictated by the end use of the product. Various technologies can be implemented to accommodate the various ultimate applications of the product.