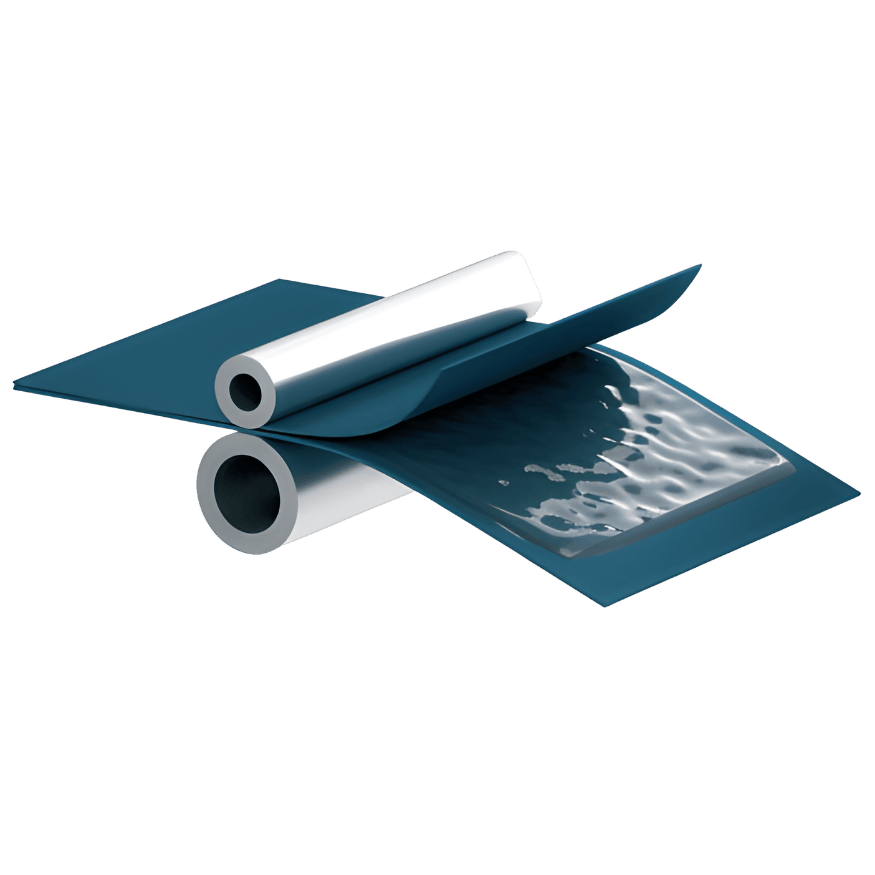

Laminating is an industrial process that involves assembling two or more layers of materials (plastic film, paper, metal foil, etc.) using a technical adhesive. This process creates a composite material that is stronger and has new properties.

These include

Dry lamination Adhesives: made with solvent-based or water-based adhesives.

Thermal lamination using heat and pressure to fuse the layers.

Calendered or flat lamination adapted to large series.

Lamination offers decisive benefits for the industry:

Mechanical reinforcement Improved tensile strength and tear resistance.

Barrier properties Protection against moisture, air, solvents and grease.

Aesthetic finishes Smoother, matt or glossy appearance.

Versatility Adaptable to a wide variety of substrates (film, paper, aluminium, foam, etc.).

Lamination is used in many sectors to create high added value technical solutions.

Thermal and acoustic insulation

Protection of wiring and panels

Assembly of lightweight composite materials

Insulating films for printed circuits

Barriers against humidity and heat

Reinforcement of membranes and sensors

Protective films for windows

Impact-resistant surface coatings

Multi-layer insulation for roofs and façades

Laminated plastic films for flexible packaging

Reinforced technical papers

Aesthetic finishes (metallic, matt, gloss)

Technical expertise mastery of dry, thermal, calendering and duplex/triplex processes.

Flexibility Production in rolls, reels or sheets according to your needs.

Full support We can work with your materials or supply them directly.

Certified quality Processes that comply with industrial and environmental standards.

Laminating uses liquid adhesives (solvent or water-based) to join several layers together. Laminating, on the other hand, uses pre-coated technical adhesive tape.

Plastic films (PET, PE, PP), paper, aluminium foil, technical foams and textiles are the most commonly used.

Yes, thanks to our flexible equipment, we can offer both prototypes and large-scale industrial production.

We work with solvent-based, water-based, hot-melt and hot-melt adhesives, depending on the performance required.

Mobility (automotive, aeronautical, rail), electronics, construction and packaging are the sectors most affected.