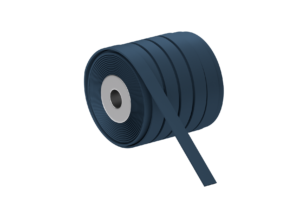

Trancannage, also known as transverse windingis an industrial process that involves winding a strip of flexible material (technical film, adhesive tape, laminate, etc.) in criss-cross layers from one edge of a mandrel to the other.

Unlike conventional winding, this method produces compact, stable and long coilsideal for optimising production rates.

Increased productivity up to 20x reduction in reel changeover times.

Optimised format Longer length of finished product per reel, adapted to customer requirements.

Material versatility Compatible with polyester, polycarbonate, fluorinated, aluminium/PET and polyimide films...

Process reliability stable winding, controlled voltage, better production continuity.

The cross-cutting process is used in a number of industrial sectors where the performance and continuity of production are key.

Electrical insulation tapes

Polyimide and polyester films for printed circuits and motors

Technical films for sensors, beams and screens

High-performance adhesive tapes for assembly and protection

Technical film reels for automated packaging

Long adhesive tapes for packaging lines

Fluorinated and polyimide films for thermal insulation and protection

Technical tapes used in extreme environments

Slitting is used in many sectors, each with its own specific requirements.

Cutting of technical films for cabling and harnesses.

Protection for interior and exterior surfaces.

Acoustic and thermal nonwovens.

Sterile film for packaging.

Non-wovens for medical devices.

Products processed in cleanrooms.

Electrical insulating films.

Technical tapes for motors and transformers.

Solutions for photovoltaics and HVAC.

Multi-material expertise mastering plastic, metal and composite substrates.

Precision equipment machines suitable for low and high thicknesses (0.47 to 4 mils).

Flexibility and customisation customised formats to suit your processes.

Commitment to quality Industrial certification and continuous monitoring in production.

Cross-winding allows for compact cross-winding, unlike single winding, which is linear. Result: more metres per reel, less machine downtime.

Polyester, polycarbonate, polyimide, fluorinated, aluminium/PET films, laminates, technical adhesive tapes.

Longer, more stable reels mean fewer changeovers, which increases production speed.

Electronics, automotive, packaging, aeronautics, energy and processing industries.