Technical Data Sheet

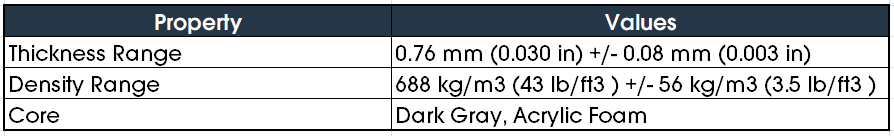

3M™ Acrylic Foam Tape Series PX5000 tapes are dark gray, double-coated acrylic foam tapes designed for attachment of automotive exterior trim parts without the use of adhesion promotor. 3M Series PX5000 tapes feature an advanced ZX adhesive system on both sides of the tape that offers excellent adhesion to medium surface energy and low surface energy substrates – as well as a variety of automotive clear coat systems.

Capable of bonding to difficult paint systems depending upon the application.

Some typical applications for 3M Series PX5000 tapes include sensor brackets, body side moldings, and pillar garnishes.

The following are recommended for successful tape applications:

Two years from date of manufacture when stored at 4°C – 38°C (40°F – 100°F) and 0 – 95% relative humidity.

Optimum storage conditions are 22°C (72°F) and 50% relative humidity.