Technical Data Sheet

3M™ Dual Lock™ Reclosable Fasteners are positive locking, hidden fasteners designed for use in a variety of attachment solutions. They consist of continuous strips of polyolefin stems with a mushroom shaped top protruding up from the backing. When snapped together the mushroom shaped caps interlock producing a strong reliable Fastener.

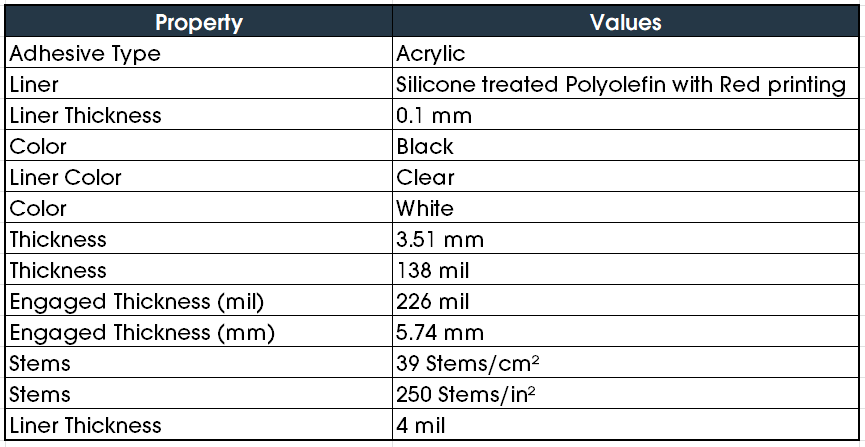

The standard Dual Lock fasteners are available in three different stem densities (170, 250 and 400) referring to the approximate number of stems per square inch. (26, 39, 62 stems per square centimeter) By inter-locking different stem density combinations you can create the strength that suits your application; more total stems give higher strength. The Dual Lock Reclosable fasteners can be mated in the following combinations of increasing closure strength: Type 170 to Type 250, Type 170 to Type 400, Type 250 to Type 250 and Type 250 to Type 400. We do not recommend using the Type 170 to 170 because it does not have enough strength for a good connection. We do not recommend using the Type 400 to 400 because it is too strong and may cause stems and heads to rip out rendering the fastener no longer reclosable.

The Dual Lock Low Profile has one stem density of approximately 705 stems per square inch and they interlock to themselves. The low profile products are not intended to mate to the standard size Dual Lock.

There are a variety of pressure sensitive adhesives available with Dual Lock to cover most application needs. The pressure sensitive adhesive makes the Dual Lock easy to use, simply remove the liner, place the Dual Lock and apply firm consistent pressure to assure good contact with the substrate you are adhering.

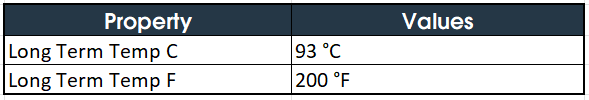

The following technical information and data should be considered representative or typical only and should not be used for specification purposes.

To obtain best performance, use within 18 months from date of manufacture.

Request for additional samples