- Produits

- Colle

- Ruban adhésif

- Mastic

- Résine

- Gaine

- Vernis Industriel

- Film adhésif

- Marques

- Converting

- Services

- Nos implantations

- Contact

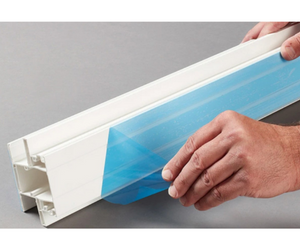

Protective films for Industrial surface protection art part of our everyday life when making a purchase. If you have bought an electronic device, appliance or a new vehicle, your item has probably benefited from protective film.

Protective film is a plastic coated material with a pressure sensitive adhesive backing that provides surface protection of products or applications. This material is commonly used to protect surfaces from dust, dirt, abrasions, scratches and contamination during stages of processing, shipping and installation.

Now that you have an understanding of protective film, it is time to look at the different types of plastics to consider.

A tough plastic that feels soft to the touch but is very strong. It is water-repellent, well-insulating and resistant to acids.

A stable light plastic that holds its shape and doesn’t stretch like PVC films. Thus, it has excellent transparency, toughness and odor retention. Useful for high-heat applications and well suited for industrial and automotive applications.

A chemically resistant and odorless plastic that performs very well over a range of temperatures. Works exceptionally well with glass or painted metals and is the preferred material for consumer industrial applications.

Also known as PVC, this is a thin thermoplastic versatile film available in a variety of forms and finishes. It has a higher level of elasticity and slick surface that works well with metal surface protection.

Co-extruded layers of plastic formed into a single sheet to combine characteristics of two different plastics. This provides a higher level of protection.

Our protective films are widely used among multiple industries for a variety of protection applications. Since the reasoning behind the use of protective film can vary from protection during transport and assembly, UV and chemical resistance, protection from scratches and dust, or resistance from temperatures, we provide a wide range of protective films for several industries.

Protective film is common for Automotive, Construction, Industrial, Electronic, Healthcare and Aerospace industries.

Our protective films are heavily used within the automotive industry. They are typically used to protect interior and exterior painted metals, smooth plastics, textured plastics, painted plastics, wheels, glass and display screens. The use of our protective films on vehicles protects from damage and dirt during the manufacturing and transport of your products.

In the construction industry, our protective films are mainly utilized for countertops, appliances, windows and doors. The use of protective film within construction is relied on heavily due to the debris and foot traffic that a site experiences.

Industries have a broad application use for protective film. Due to the wide range of applications, this typically requires customized protective film pieces to fit equipment or new manufactured products.

The protection of electronics is very important to maintain the aesthetic of the product for consumers. Therefore, our protective films for electronic equipment provide protection against damage during packaging, shipping and installation.

Medical devices are a common application for protective film within the healthcare industry. To ensure long-lasting performance of these expensive devices, the use of our protective films prevents wear and tear.

Protective film ensures high value aircraft parts are safe from scratches, abrasions and small impacts. Applying protective film can increase the longevity of aerospace parts that have a high replacement cost.

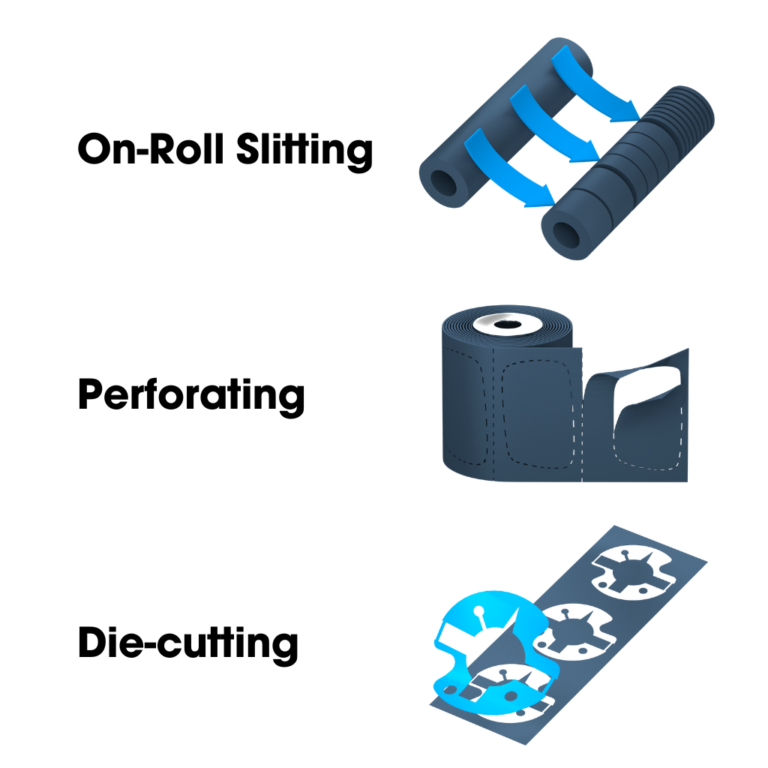

For your specific application, a simple roll of protective film may prove to be a monotonous task. You have to cut multiple strips at different lengths and you end up with considerable waste and time spent applying the film. Luckily, our expertise in converting protective film will increase your efficiency and reduce waste. Discover our capabilities with this type of material:

When determining how best to convert protective film to match your application, speaking with our expert can provide the right guidance to ensure efficiency and cost effectiveness.

For all materials and products that are purchased it is important to guarantee a product with no defects. Thus, protective film provides the assurance you need to deliver your products damage free.

Selecting the right protective film for your protection specifications can be daunting. You need to consider what material you are bonding the protective film to, what film thickness is best, does it need to be UV resistant, along with multiple other factors. You can access our protective film selection guide to give you an idea of where to start. Or, simply submit a request form below to speak with our protective film experts.