Adhesive tapes are materials in film form onto which an adhesive mass is applied. Thanks to their ease of use and versatility, these products are used for both material assembly and a wide variety of technical applications. Here is an overview of the use of adhesive tapes in industry.

Bonding and the use of double-sided adhesive tapes are recent methods of joining materials, which are constantly improving, thanks to advances made by manufacturers.

Assemblies using double-sided adhesive tapes have several advantages:

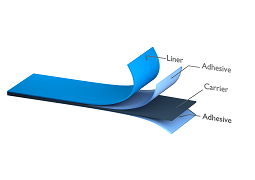

A double-sided tape is made up of:

There are three families of adhesive compounds:

Bonding steel stiffeners to road signs

Fixing and dressing of signs

Bonding of foam for seats

Fixing aluminum profiles

Gluing stainless steel, wood, etc.

Single-sided tapes can be used for a wide range of technical applications.

Here are some ways to use single-sided tapes

Masking and sparing tapes are used for the temporary protection of surfaces.

For example, masking tapes are used for masking, paint application and sanding/blasting operations. Due to their high mechanical strength, they can also be used for repairs.

EPDM (Ethylene Propylene Diene Monomer) single-sided foam adhesive tapes are elastomers that fill gaps and provide a seal.

Example: Marking or marking with adhesives. Vinyl adhesives for floor marking to enfore social distancing measures in the case of COVID-19.

Adhesive tapes are widely used in the packaging industry.

Example: Adhesive Kraft is a paper on which an acrylic, silicone or rubber adhesive mass is applied.

Foam-type adhesive tapes can be used to dampen vibrations caused by industrial equipment.

For the most technical applications, Kapton® adhesive polyimide tapes provide both very good electrical and thermal resistance. Adhesive tapes for electrical insulation are used in the railway industry, for example.

Before applying an adhesive tape to a surface, it is essential to ensure that the surface is clean, so as to guarantee an optimal bond.

However, since adhesive tapes are not intended for structural applications, surface preparation is limited to degreasing the surfaces to be joined.

Adhesive tapes are used everywhere, in industry as well as in our daily lives, for non-structural or semi-structural applications.

Our teams will answer you as soon as possible