ADDEV Materials’ core business is the conversion of materials into films, tapes, or parts. Below are our custom converting solutions for the POS industry.

We are able to supply custom width adhesive rolls, from 4mm to 1500mm. Thanks to the diversity of our cutting processes, we are able to supply all types of parts for POP, allowing us to meet your specific requests.

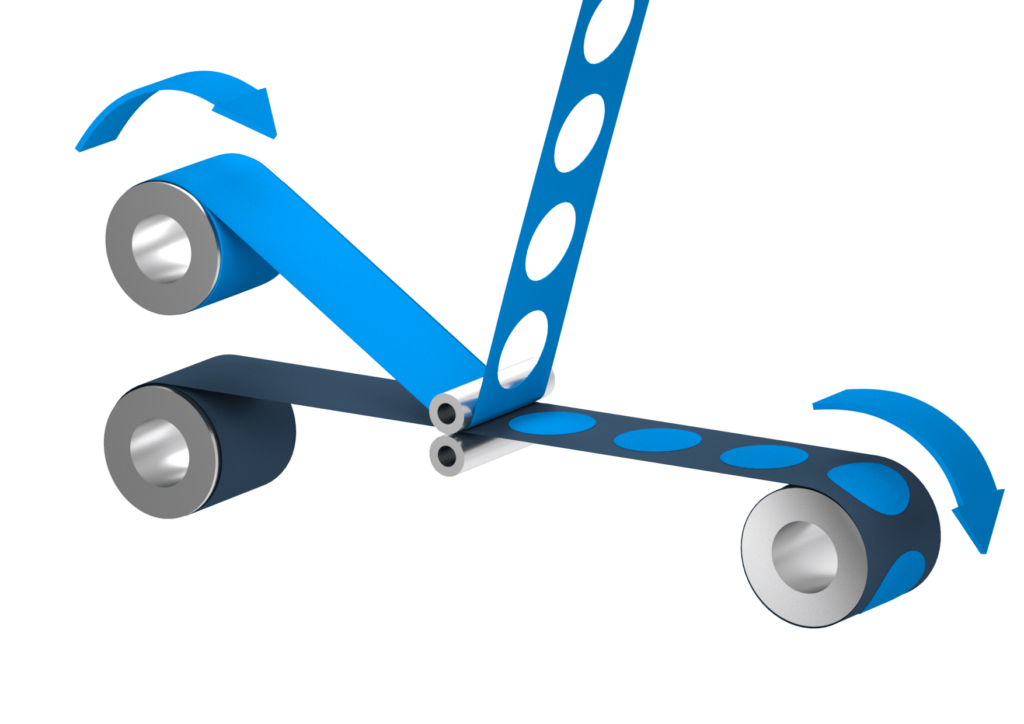

Rotary Cutting

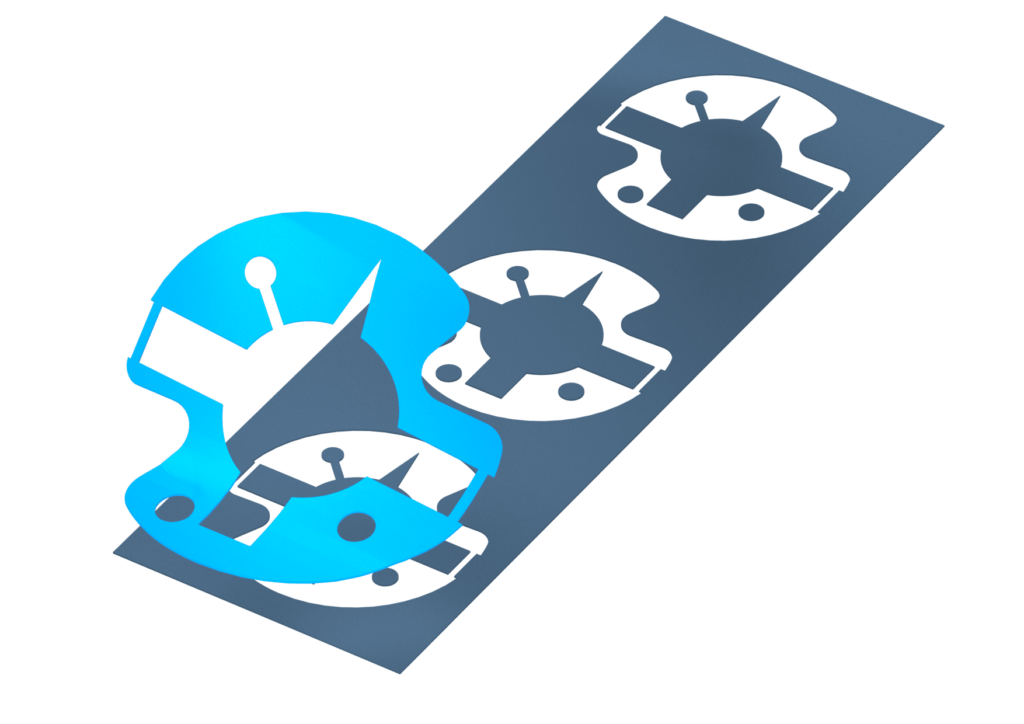

Flat bed cutting & Die Cutting

Do you need to add an adhesive layer to a particular film, like PVC? With our lamination facilities, we are able to fulfill this need for your POP assembly as well.

As a POP manufacturer or assembler, having rolls of pre-cut adhesvie parts, equipped with gribbing tabs, allow you to save precious time on the assembly of your POP.

With world-class partners, ADDEV Materials can provide access to brand name adhesives of consistent quality. You will be able to optimize your adhesive operations and gain in productivity.

Our teams will answer you as soon as possible