Consisting of a viscoelastic adhesive on each side, acrylic viscoelastic foams are high performance adhesives. Below are the main benefits of these products.

The main characteristic of viscoelastic acrylic foams is their ability to deform. This property is particularly interesting because it allows materials with different coefficients of expansion to be joined together without the risk of the joint breaking.

In addition, this product is a strong adhesive with semi-structural properties, which makes it possible to join many materials used in specialty vehicles, such as sheets or panels.

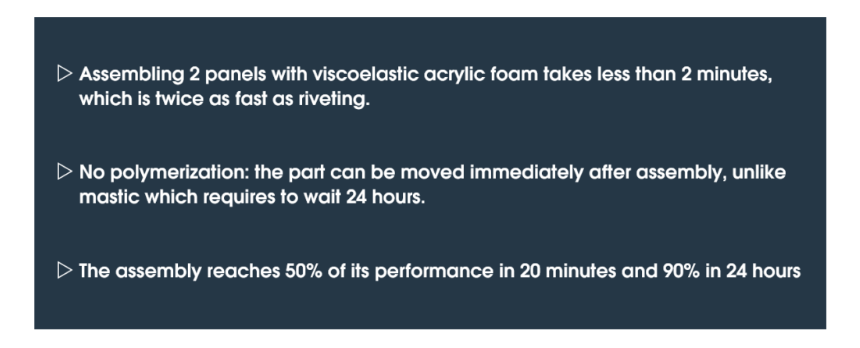

The main advantage of double-sided adhesives is their ease of application.

Coupled with exceptional mechanical characteristics, this ease of application allows for assemblies that rival traditional fasteners, because:

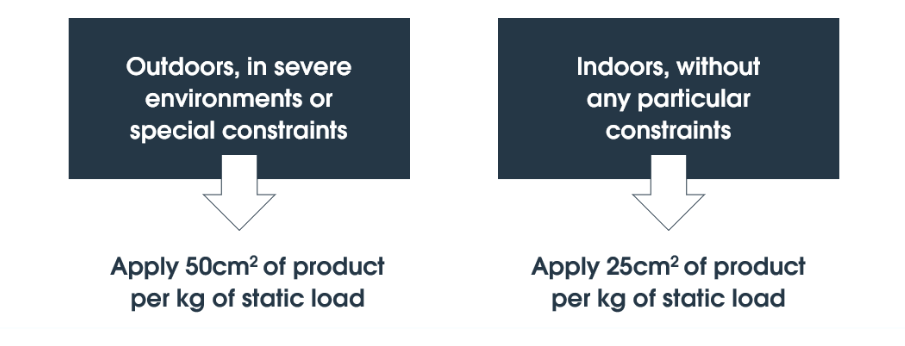

The application of a viscoelastic acrylic foam is done in several steps:

Acrylic viscoelastic foams are particularly appreciated by designers, as they allow the assembly of a wide range of materials without leaving any traces.

In addition, these products have the advantage of making cleaning easier because of the smoothness of the assemblies, which keeps the surfaces shiny and clean.

Compared to metal fasteners, using such thin polymer products not only makes vehicles lighter but also reduces the thickness of the parts.

This viscoelastic foam has the particularity of ensuring water and dust tightness of assemblies, even at extreme temperatures (-20°C to + 120°C for most references). This aspect is particularly important to meet the temperature resistance requirements of certain special vehicles such as refrigerated trucks or construction equipment.

These products also have a good resistance to:

In addition to providing an excellent seal, viscoelastic foams are capable of damping vibrations, a property much sought after by OEMs and manufacturers of special vehicles.

Under similar road conditions, the assembly between two sheets was tested by an independent laboratory. An average vibration gain of 40% and an average noise gain of 30% were measured.