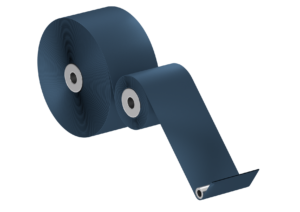

At ADDEV MaterialsDecoiling is an essential stage in the converting process, enabling unwind, rewind and repack adhesive products and technical films to meet your specific needs. This know-how guarantees perfect adaptation to industrial constraints, whether for adhesive tapes, protective films, insulating materials or assembly solutions.

Le unwinding consists of transferring a product (tape, film, liner) from a master roll to a roll adapted to the customer's needs. This operation can involve several complementary stages:

Rewind with change of mandrel (diameter, marking, customer specifications).

Continuous cutting if necessary.

Reconditioning in shorter or wider rolls.

Peeling offers a number of benefits:

Dimensional flexibility rewinding to exact lengths and widths.

Process optimisation time-saving on production lines thanks to specially-adapted rollers.

Consistent quality Controlled tension, no bubbles or defects.

Multi-market compatibility Suitable for technical adhesives (3M, tesa, Nitto, Eurobands) and customised films.

Protective films for bodywork and interiors.

Adhesive tapes for assembly and insulation.

Insulating materials for cabling and harnesses.

High-performance technical films for surface protection.

Electrical insulation tapes for transformers and motors.

Thermal or dielectric protection films.

Reconditioned sealing and jointing tapes for fast installation.

Protective films for building sites and sensitive surfaces.

Multi-material expertise adhesives, technical films, insulation.

Advanced conversion capabilities slitting, lamination, cross-canning and die-cutting.

Partnerships with major brands 3M, tesa, Nitto, but also private label solutions.

Tailor-made approach Adaptation to the constraints of your production lines.

Unwinding is a process used to rewind a master roll into adapted reels (dimensions, specific mandrels).

All types of technical tape (assembly, protection, electrical, sealing) and technical film (protection, insulation, packaging).

Le unwinding adapt length and packaging.

Le slitting reduces the width of a roll into several strips. The two processes often complement each other.

Yes, our equipment can transfer to different diameters and custom mandrels (including marked mandrels).