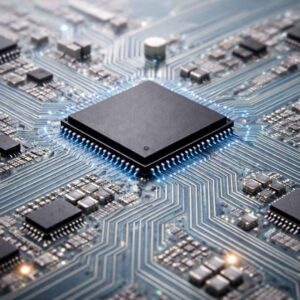

In the electronics industry, assembly reliability, thermal management and component protection are critical issues. The adhesive solutions for electronics now play a central role in the design, assembly and durability of electronic equipment, from circuit boards and batteries to screens and enclosures.

ADDEV Materials supports electronics manufacturers with a comprehensive range of technical tapes, functional films, foams and industrial adhesives, adapted to the most demanding electrical, thermal and mechanical constraints.

Electronic applications impose specific constraints on the materials used. Adhesive solutions must meet stringent requirements in terms of safety, performance and regulatory compliance.

The main characteristics sought include:

Reliable electrical insulation to prevent short circuits and discharges

Thermal resistance to withstand the heat generated by the components

Low outgassing to protect sensitive components

Compatibility with miniaturisation equipment

Fire resistance (UL, IEC standards)

Dimensional stability over time

These constraints make adhesive solutions for the electronics industry functional elements in their own right, far beyond a simple fixing role.

An adhesive solution for electronics brings together all of the tapes, films, foams and adhesives used to assemble, insulate, protect or manage heat within electronic equipment.

This includes

Electrical insulating tapes

High-temperature tapes

Optical protection films

Technical foams

Thermal pads and films

Precision industrial adhesives

The use of technical adhesive solutions offers many advantages over traditional assembly methods (screws, clips, welding).

Key benefits :

Clean, precise assembly, without mechanical stress

Weight reduction components

Optimising space, essential for miniaturised devices

Vibration absorption and shocks

Improved reliability over the long term

Design flexibility for engineers

Adhesive solutions for the electronics industry cover a broad spectrum of applications, from mass production to high added-value equipment.

Tapes and adhesives are used for :

Electrical insulation of runways

Maintaining components

Protection against moisture and dust

Vibration damping

The polyimide tapes, for example, are widely used for their temperature resistance and dielectric properties.

In lithium-ion batteries and storage systems :

Cell attachment

Electrical insulation

Thermal management

Fire safety

Technical foams and thermal films play a key role here in terms of reliability and safety.

Optical films and adhesives enable :

Protecting sensitive surfaces

Blending without bubbles or residue

Preserving optical quality

They are used on LCD and OLED screens and touch interfaces.

Adhesive solutions ensure :

Watertight enclosures

Fixing internal supports

Protection against mechanical and environmental damage

The increasing power of electronic components generates a lot of heat. Poor heat dissipation has a direct impact on lifetime and performance.

ADDEV Materials offers thermal management solutions such as :

Thermal pads

Dissipative films

Gap-filler foams

Adhesive thermal interfaces

These solutions ensure efficient heat transfer between components and heatsinks, while maintaining reliable electrical insulation.

ADDEV Materials is positioned as a technical partner for electronics manufacturers, far beyond the simple supply of materials.

Our strengths:

Wide portfolio of adhesive solutions for electronics

Partnerships with benchmark manufacturers

High-precision cutting capabilities (die-cutting)

Technical support right from the design phase

Solutions that comply with electronics industry standards

Electrical insulating tapes, polyimide films and insulating adhesives are commonly used to prevent short circuits and ensure the safety of electronic equipment.

Thermal management is based on the use of thermal pads, dissipative films and gap-filler foams, which ensure efficient heat transfer.

Yes, self-adhesive solutions can reduce both size and weight, making them particularly suitable for miniaturised equipment.

Some solutions, such as polyimide tapes or high-temperature adhesives, are designed to withstand high thermal conditions.

Yes, ADDEV Materials supports its customers with customised solutions, including precision cutting and adaptation to the specific constraints of electronic projects.