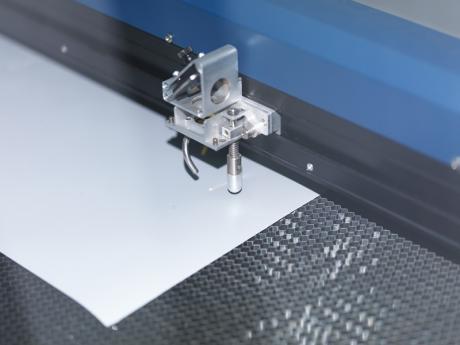

This is a high-precision industrial process that uses a concentrated beam of light to cut, engrave or mark different materials. Unlike mechanical methods, the cutting head does not touch the surface: this prevents any deformation or damage to the substrate.

Non-contact cutting No risk of pressure or sticking to the material.

Extreme precision Complex shapes with high repeatability.

Versatility Compatible with a wide range of substrates (plastic film, foam, paper, fine metals, technical adhesives).

Flexibility production: single unit, small or large series.

Laser cutting is not just a high-performance technology: it brings direct benefits to your industrial projects.

Superior finish quality clean, burr-free edges.

Time saving no changing or cleaning of blades.

Adaptability from prototype to industrial volume.

Multi-layer cutting The adhesive can be cut away without damaging the protective liner.

Cost optimisation Less material waste thanks to greater precision.

It is used in many industrial sectors where precision, reliability and flexibility are required.

Cutting of seals, films and technical foams.

Adhesive parts for thermal and acoustic insulation.

Cutting insulating adhesives.

Protective and heat dissipation films.

Cutting of films and adhesives for medical devices.

Technical parts for sensors and diagnostic equipment.

Insulation and protection in electrical systems.

Cutting of high-performance adhesive tapes for industrial equipment.

At ADDEV Materials, we combine technical expertise and industrial capacities to offer you a made-to-measure service:

High-performance machinery High-precision lasers for adhesive and multi-material substrates.

Personalised support from design to delivery.

Multi-process capability laser, as well as mechanical, rotary and flatbed cutting.

Rigorous quality control conformity assured for each series.

Sustainable approach reducing waste and optimising the use of raw materials.

Yes, it allows you to cut the adhesive without cutting the liner, making it easy to handle and apply.

Plastics, paper, film, foam, fine metals, technical adhesives, industrial textiles.

Depending on the material, the tolerance can be as little as a few hundredths of a millimetre.

Yes, especially for complex shapes or varied production runs: no need for expensive tooling such as cutting dies.

Absolutely. The speed of implementation means that prototypes or small series can be produced before industrialisation.