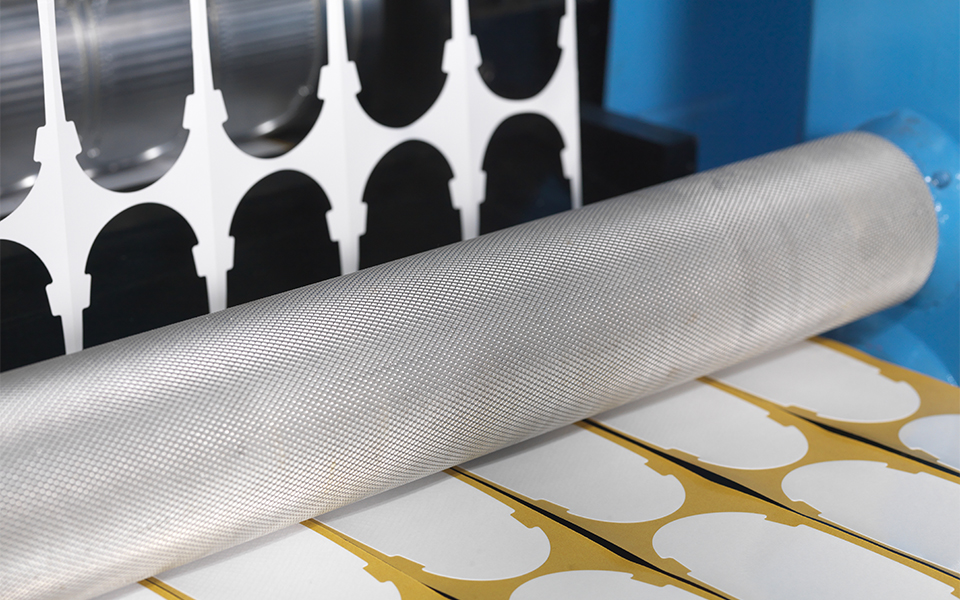

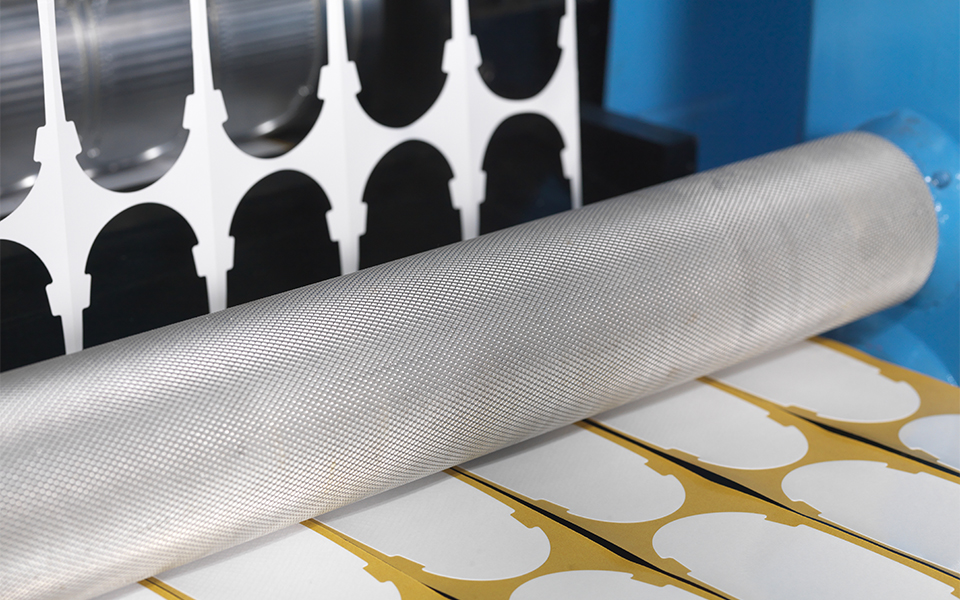

L’embobinage, une solution pour des process optimisés Une solution d’excellence Le trancanage, ou enroulage continu, est une technique clé dans l’industrie du converting qui consiste à transformer des matériaux flexibles, tels que des films, des adhésifs, des mousses ou autre matériaux rigides, en bobines de grande longueur. Contrairement aux découpes traditionnelles en rouleaux standards, le […]

Discover Nomex® 410 What is Nomex® 410? Nomex® 410 is a high-density insulating material that has been a benchmark in the industry for over 50 years. Its excellent dielectric strength, mechanical toughness, and flexibility, have made Nomex® 410 an high-performance, versatile material widely used across multiple industrial applications. Whenever you require durability and reliability, even in extreme, […]

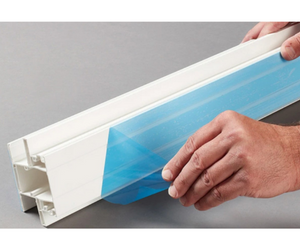

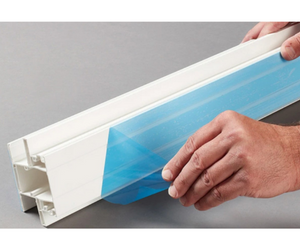

Discover Protective Film What is Protective Film? Protective films for Industrial surface protection art part of our everyday life when making a purchase. If you have bought an electronic device, appliance or a new vehicle, your item has probably benefited from protective film. Protective film is a plastic coated material with a pressure sensitive adhesive backing […]

Aluminum Foil Tapes There is a wide range of applications that aluminum foil tapes can be used for due to its versatility. It is widely used in all kinds of industry application, such as HVAC, electrical installations, constructions… from manufacturing to construction. Its quality has therefore made its way into the aerospace industry. Aluminum foil […]

Robotic tape system 3M and Innovative Automation have collaborated to create a robotic tape system for applications that require precision, repeatability and high output. The RoboTape™ for 3M™ Tape allows manufacturers to take advantage of the benefits of 3M Tape in their assembly processes while maximizing production throughput, improving quality, reducing or re-tasking manual labor […]

Custom material processing for specialty vehicles To make life easier for our customers, ADDEV Materials offers custom die-cut tapes. Below are just a few of our converting solutions tailored to the shaping of specialty vehicle materials. What needs does custom cutting meet? In specialty vehicles, there are as many assembly needs as there are applications. […]

Full-service supplier solutions for a complicated supply chain Supply Chain Solutions Recent supply chain issues within the window & door industry have caused manufacturers to find solutions to constraints linked to material availability, increased costs, and turnaround times. In a recent survey by Industry Pulse, 62% of respondents indicated they will prioritize domestic suppliers over […]

Specialty vehicle assembly – sealing Ambulances, tractors, refrigerated trucks, motor homes, etc. These specialty vehicles all require the use of assembly and sealing solutions. For example, for campers and caravans, many applications are possible. Let’s know more about Specialty vehicle assembly – sealing and how ADDEV Materials can be your partner of choice for your projects! Fixing […]

Assembly solutions for specialty vehicles Specialty vehicle applications require versatile, durable, and fast-acting assembly solutions. The advantages of using ADDEV Materials’ sealants, adhesives, and tapes include: Better sealing Ease of use and speed Lighter weight assemblies Less corrosion problems Vibration damping Discover the details of our solutions. Assembly of specialty vehicles Specialty purpose vehicles are […]

Material assembly: your ADDEV’s Guide Material assembly consists of joining 2 materials together, in order to create a mechanical link. In this article we will detail the different techniques to help you determine which solution meets your needs. What is a joint? All materials can be joined, but the efficiency of the joining will depend […]