When they leave the manufacturer’s premises, electrical insulators are available in rolls or boards. ADDEV Materials puts its expertise at the service of its customers by proposing the functionalization and the cutting of these insulators, in order to meet the specifications of the most demanding customers.

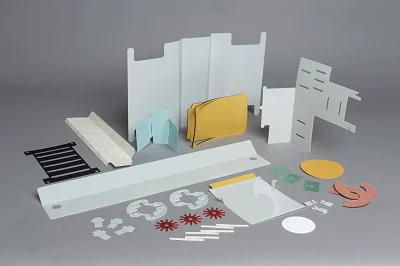

The techniques for transforming electrical insulators depend on both the starting materials and the customer specifications. ADDEV Materials thus offers three types of custom cuts as well as the machining of massive parts.

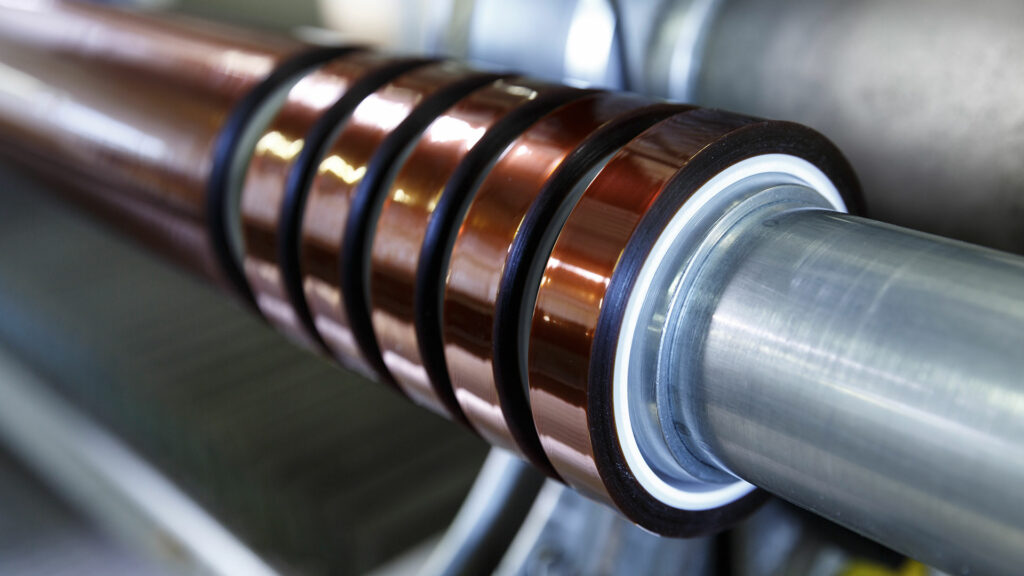

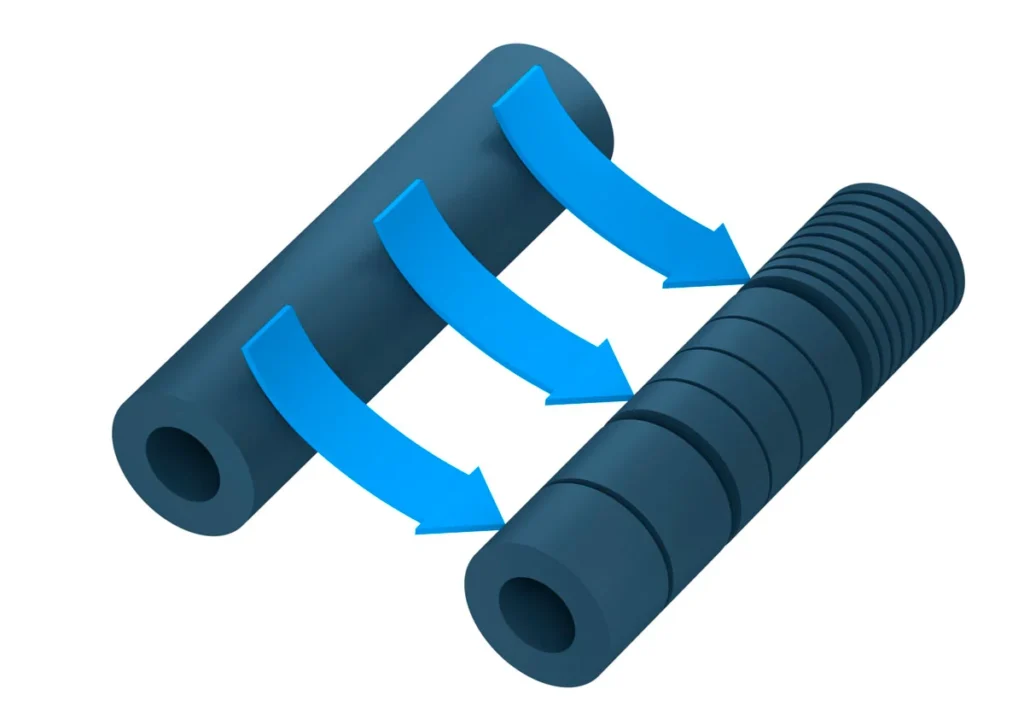

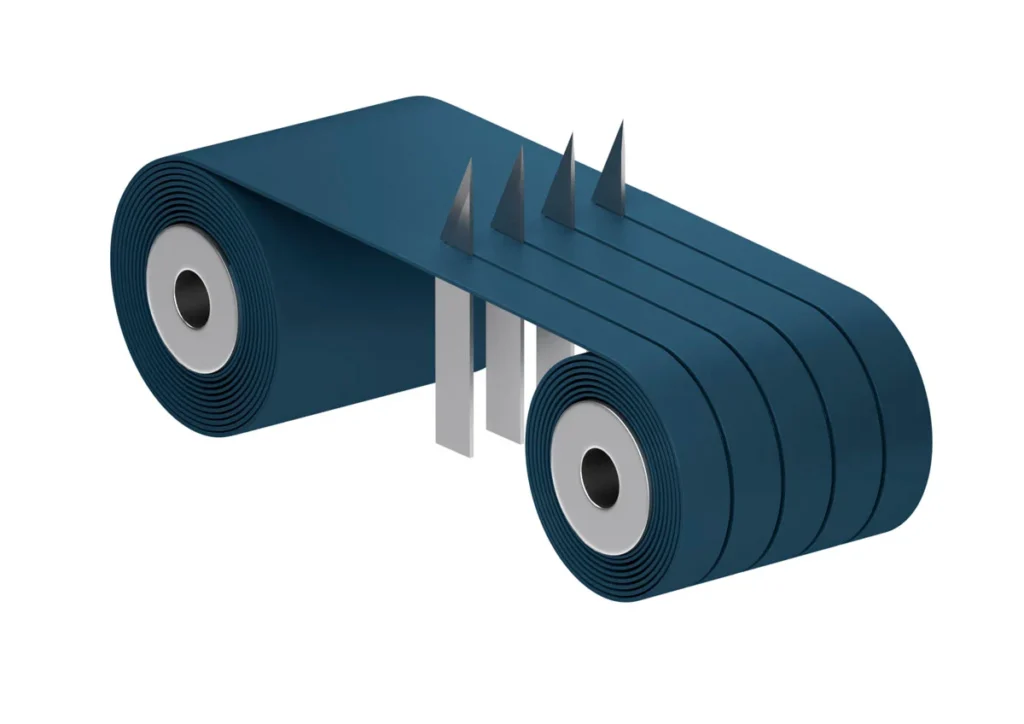

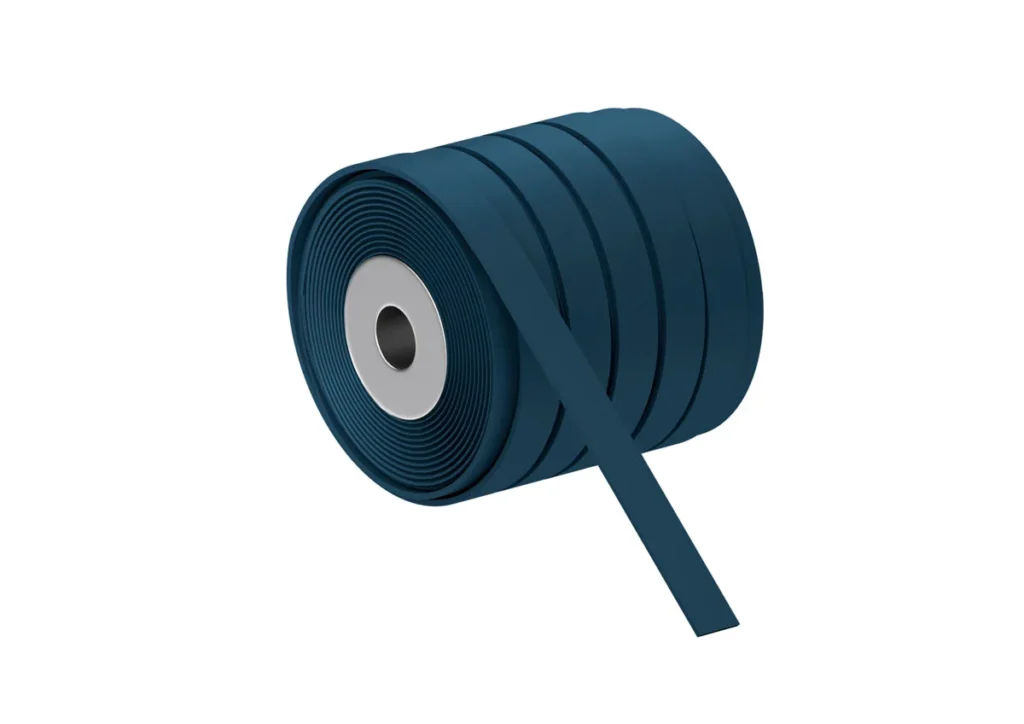

Roll cutting is for films stored in reel form . Several methods are available depending on the needs.

ADDEV Materials also has slitting machines to unwind and rewind coils while performing continuous cuts;

Format cutting is for all flexible products . It consists of cutting products in formats such as A3, A4 or any other format specific to a customer.

Cutting into pieces is dedicated to thick materials (thickness to be specified). Four types of processes are possible for cutting into parts for high precision sectors such as electronics, medical or aeronautics. ADDEV Materials is able to produce:

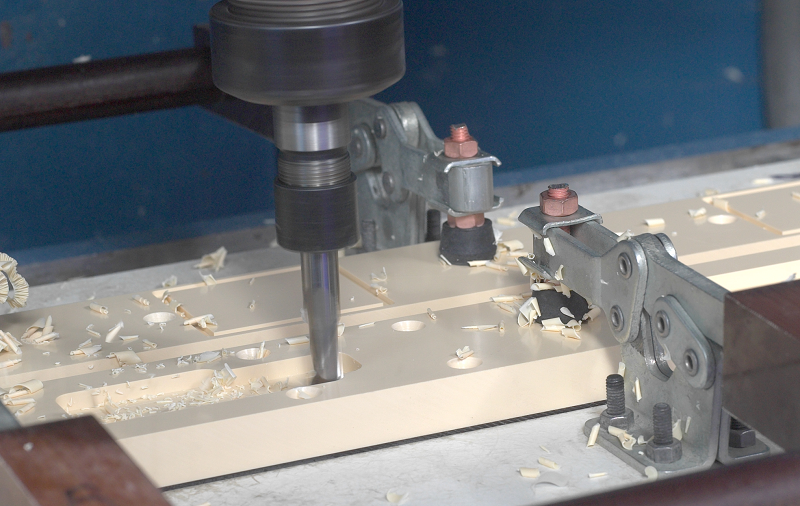

Traditional machining (sawing, milling, turning) or by numerical control makes it possible to produce complex massive parts with reduced tolerances, without tooling costs.

ADDEV Materials has machines suitable for machining parts of all sizes, to meet the needs of small and medium series. ADDEV Materials is able to machine the following materials:

When it comes to electrical insulation, ADDEV Materials stands out thanks to:

A customer needs 10 insulation cut from boards and a 2D plan provided in DXF format. ADDEV Materials will be able to meet this demand because it has digital cutting machines that can produce small series. In addition, thanks to prototyping , it will be possible to check that the part corresponds to the needs of the design office and to correct if necessary before launching the series or the final tooling.

A customer wants 20 cm and 10 cm polyester insulation rolls, containing an adhesive layer. ADDEV Materials will therefore turn to the manufacturer who will supply it with 1 m uncoated polyester rolls. First, these raw rolls will be glued then they will be cut into smaller rolls and sent back to the customer, ready to be used.

ADDEV Materials offers real added value to its customers. The expertise of its teams thus enables:

With its tailor-made or custom cutting solutions, ADDEV Materials is able to deliver to its customers materials that can be used directly on their production lines, which represents a definite gain in productivity.

With an integrated machine park, ADDEV Materials delivers to its customers the product cut to measure, to adapt perfectly to the final use. There are therefore no waste to manage for the customer; the product is perfectly suited to the application.

The role of ADDEV Materials is to transform the insulating films in order to adapt them to the needs of the customers , whether it concerns a few parts or several tens of tons of material. In this way, ADDEV Materials positions itself closer to the customer’s needs.

ADDEV Materials has been a specialist in electrical insulation for over 50 years. Thanks to its international presence, ADDEV Materials is thus able to guide any customer and support him in the development of his product.

Because it has both the technical knowledge and the necessary means of transformation, ADDEV Materials is a privileged interlocutor for the supply of tailor-made and quality electrical insulation materials.

Our teams will answer you as soon as possible