Whatever the customer’s need, ADDEV Materials has the solution for custom cutting and cutting to size.

Our teams are committed to deliver the transformed or cut materials in the most accomplished form so that they can be used directly on the production lines of their customers and bring them additional productivity.

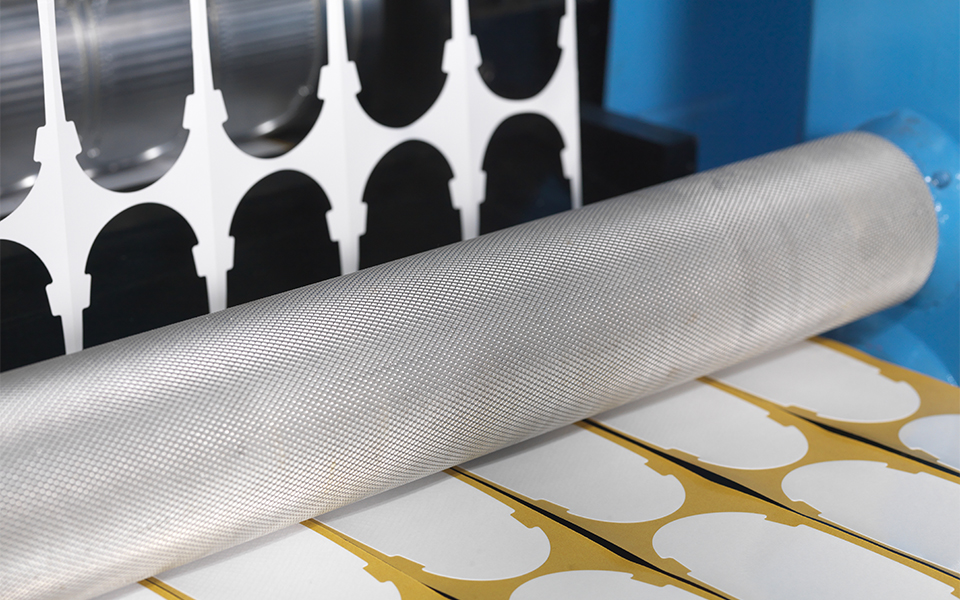

Rotary cutting machines cut out simple or complex shapes from an adhesive tape, film or paper stock, using a rotating tool whose profile is the same as the profile of the cut.

Cutting options :

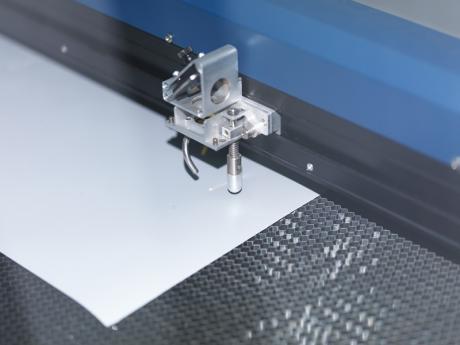

One of the types of cuts which laser cutting is suited to is kiss cutting, i.e. where the top layer is cut without cutting through the underlying layer.

The attractive feature of laser cutting is that the cutting head does not touch the surface, and consequently does not distort the product or stick to it. This makes laser cutting well suited to complex cuts, with the complexity often resulting from the composition of the product and/or its thickness.

ADDEV Materials machines are also able to cut through adhesive-coated backings without cutting through the release liner.

Other benefits:

CNC cutting is used to produce prototypes as well as to perform small and medium-sized production runs on parts of all sizes (from a few millimetres to several metres).

ADDEV Materials machines can handle unlimited lengths since they are fitted with an automatic material unwinding and conveying system.

Press (die) cutting machines stamp a specific shape out of the material.

The press cutting machines and associated dies used at ADDEV Materials can be adapted to meet all the technical and logistic issues that arise, which may relate to the type, shape or thickness of the material or to the application of the machine to medium-sized and large production runs.

ADDEV Materials can quickly and efficiently die-cut every product in its various ranges of films, insulating materials and single- and double-sided tapes. ADDEV Materials technicians work to the customer’s specification to create the ideal die-cut shape that will satisfy the customer’s requirements