ADDEV Materials studies your requirements in order to provide fully adapted solutions from design to implementation of parts cut to the required shape.

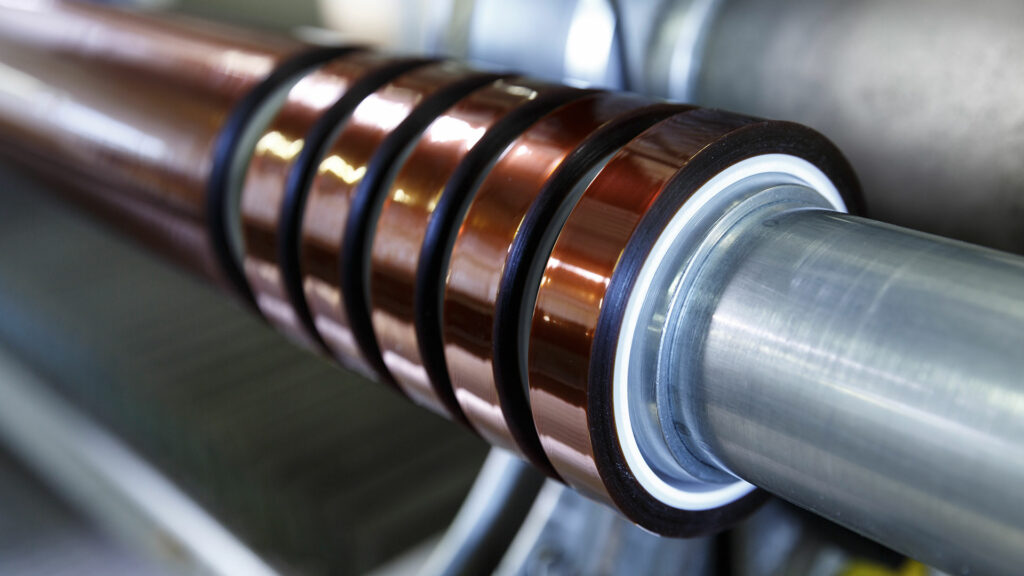

The materials (films or adhesive tapes) are stored in jumbo rolls, which the ADDEV Materials teams cut to the required dimensions. Several types of presentation are possible, depending on requirements.

All aspects of the roll cutting process are taken into account, with the aim of saving time on the customer's production line. Each product is delivered in a finished state, with the ideal dimensions for the customer.

Cutting is a process used to cut a roll of wound adhesive film. The state-of-the-art machines operated by ADDEV Materials can handle adhesive materials from 40mm to 1.5m wide.

ADDEV Materials uses automated slitting processes that minimise roll changeover times. The various roll slitting techniques ensure optimum slitting quality for customers.

Our resources :

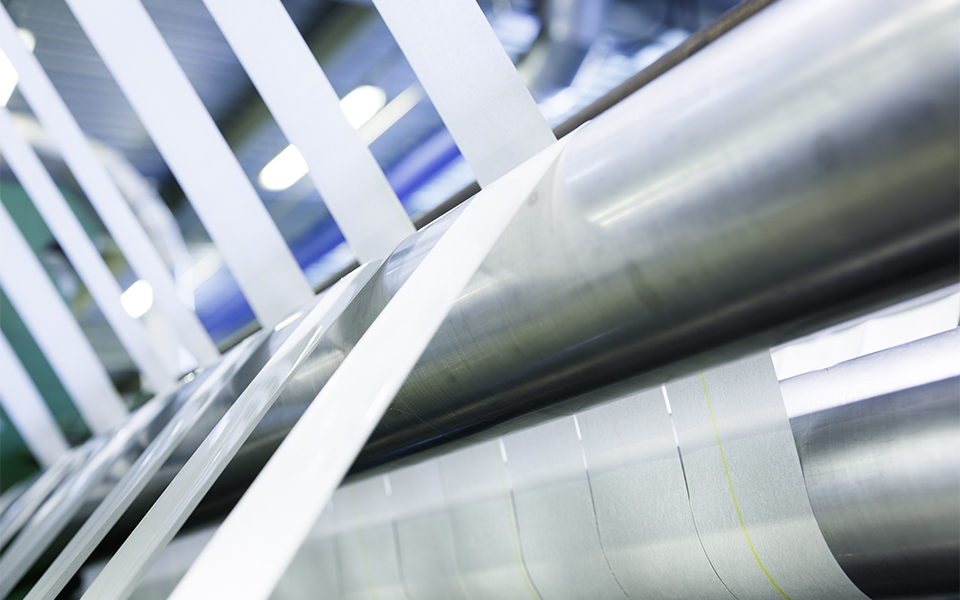

Slitting and rewinding (or "off the reel" slitting) are carried out to divide a parent reel into reels of different widths and lengths.

Thanks to its high-tech machinery, ADDEV Materials can meet all requirements for non-adhesive materials with thicknesses ranging from 0.23622 mils to 39 mils.

The ADDEV Materials teams guarantee reduced slitting and roll changeover times, while ensuring top-quality slitting. The equipment installed can handle both small and large production runs.

Do you need the slitting and rewinding operation to be carried out in a controlled atmosphere? ADDEV Materials is equipped with ISO 7 class laminar flow installations.

If you have any questions about thicknesses, tolerances we can achieve, internal and external diameters, widths or weights, please don't hesitate to contact us.

Transverse winding is a process by which a strip of flexible material (technical film or adhesive tape) is wound in a specific way, from one side to the other, across the width of a core to form layers.

This winding method makes it possible to create reels of film or adhesive tape from a parent reel, containing hundreds or even thousands of metres of product on a single reel.

This technique makes it possible to obtain a greater length of finished product in a volume format adapted to the customer's processes.

By using these reels, total changeover time can be reduced by a factor of up to 20, improving production line productivity.

The cut strips are wound onto the reel, one layer at a time, using a cross-winder. This process can be carried out on many different types of film, such as :

Machine capacity :

ADDEV Materials' slitting machines allow the product to be unwound and rewound, with continuous cutting if required.

The product can be repackaged in shorter and/or wider lengths, according to customer requirements, or interchanged on a customer-specific mandrel (different diameter, marking, etc.).

Slabbing is a process consisting of folding a material in half (or more) along its length, while wrapping it around a roll.

ADDEV Materials produces rolls of folded materials, such as geotextiles for gardening or construction/civil engineering applications.